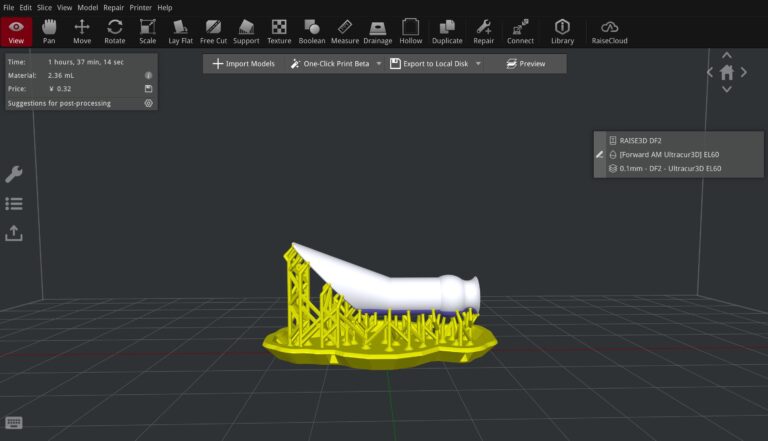

In this innovative medical practice, the Raise3D team utilized the DF2 series DLP 3D printer to print high-precision medical prototypes, achieving rapid prototyping and validation of the stent. This provides critical technical support for the Zhongshan Hospital team in formulating the subsequent treatment plan.

Zhongshan Hospital, Fudan University. Image source: Official website of Zhongshan Hospital, Fudan University (https://www.zs-hospital.sh.cn/zhuanye/)

A Rare Case, Bringing New Challenges

Zhongshan Hospital is China’s first comprehensive national medical center. Dr. Yu Haoran, a current member of the hospital’s otolaryngology team, once treated a special pediatric patient born with completely closed bilateral anterior nostrils, with only tiny pits remaining. This condition is extremely rare, and has no successful treatment cases reported worldwide.

The main challenge in treating this disease is the patient’s underdeveloped nasal alar cartilage and nasal appearance. Even if surgery is performed to open the nasal cavity, the surgical cavity tends to close quickly without structural support. Traditional methods used for posterior nasal atresia—such as inserting a tracheal or drainage tube—would cause strong discomfort, impair nasal function, lower quality of life, increase caregiving difficulty, and raise the risk of infection or necrosis. At the same time, the treatment team also noticed that there is still a gap in the market for nasal stents suitable for infants and young children, and there is a lack of reliable solutions.

Thus, the team faced the urgent challenge of developing an entirely new customized solution in a short period of time.

Left: The patient with nasal atresia who had to undergo emergency tracheotomy for ventilation; Right: CT image of the patient’s nasal area.

Image source: Zhongshan Hospital team

3D Printing Enables Rapid Customization

After a multidisciplinary team (MDT) discussion with plastic surgery experts and with the support of the « Fu Qing Scholar » Scientific Research Innovation Project Fund from Fudan University Shanghai Medical College, the team decided to use 3D printing technology to customize an individualized nasal stent prototype for the patient.

The advantages of 3D printing were fully demonstrated in this case:

- Rapid Response: 3D printing technology supports high-frequency, rapid prototyping, and validation to meet urgent medical needs.

- High Customization: Designs can be tailored to the patient’s unique anatomy.

- Low-Cost Prototyping: Compared to traditional manufacturing, 3D printing is more cost-effective.

- Pandemic Flexibility: During the COVID-19 pandemic, the conditions for prototype validation in hospitals were limited, and 3D printing technology provided a flexible solution.

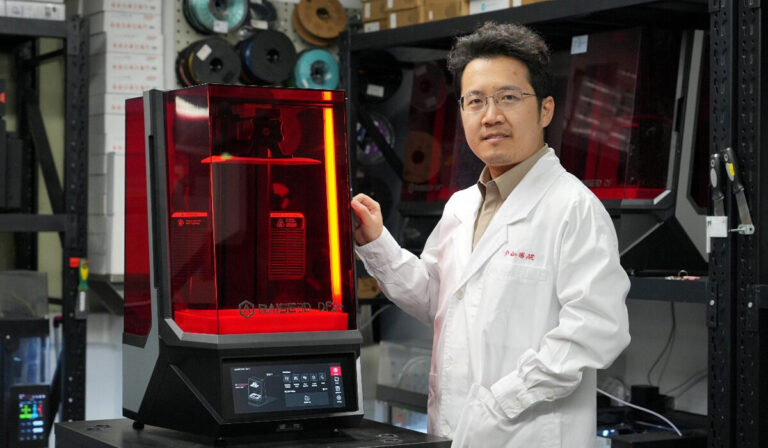

Based on these advantages, Dr. Yu contacted Raise3D’s China branch and learned that Raise3D is developing a new DLP 3D printer – Raise3D DF2. The DF2 is a DLP 3D printer with stable performance and high printing accuracy, supporting a variety of resin materials. At the same time, the Raise3D team has excellent printing service capabilities, responds quickly, assess customer needs, and provide the most suitable solutions for users.

All parties agreed to use the DF2 for the prototype design and validation of the nasal stent.