Chicago (IL), September 8th, 2025 – Raise3D, a global leader in additive manufacturing solutions, is proud to announce the launch of the E3 IDEX 3D printer today at FABTECH 2025. Forged from the E2 and E2CF, the E3 is designed to meet the evolving demands of modern manufacturing. Engineered for precision, efficiency, and versatility, the E3 empowers businesses and creators to push the boundaries of prototyping and end-use part production.

The Raise3D E3 3D printer is built to deliver high-speed, stable, and precise prints, with capabilities reaching up to 200 mm/s for composite materials and TPU. Compatible with composite filament print head and the newly launched Flexible Filament Auxiliary Feeder, E3 is an ideal solution for industries requiring complex prints with flexible filaments, composite filaments, and exceptional surface finishes.

Raise3D E3

Key Highlights of the E3:

1. Flexible Filament Auxiliary Feeder

The E3 is compatible with Raise3D’s Flexible Filament Auxiliary Feeder, an auxiliary feeding and buffer system that increases the feed rate of flexible filaments such as TPU. The higher TPU feed rate enables the E3 to print high-quality TPU parts at up to 200 mm/s. The Flexible Filament Auxiliary Feeder also expands E3’s compatibility with more flexible and elastic materials.

Flexible Filament Auxiliary Feeder on the E3

2. Printing Capabilities for Composite Filament and Pro Ironing

With the optional composite filament print head, the E3 supports a variety of composite filaments, including Raise3D’s latest Hyper Speed PLA Pro Filament. With the new Pro Ironing feature – a synergy of the E3 printer, the latest Hyper Speed PLA Pro or Industrial PETG ESD filaments, and the slicing profile in ideaMaker, E3 delivers an improved surface quality comparable to injection molding, with an average roughness (Ra) of less than 2 µm.

Part printed with Hyper Speed PLA Pro on the E3, Pro Ironing enabled

3. IDEX

The E3 is an IDEX 3D printer that supports multiple print modes including mirror mode, duplication mode, dual-color, and dual-material printing. With a maximum print speed of 200 mm/s and IDEX capabilities, the E3 can double production output by printing identical models simultaneously, maximizing efficiency and throughput. Furthermore, the IDEX system allows the E3 to print two materials with significantly different printing temperatures.

E3’s IDEX

4. Auto Bed Leveling and Substrate Printing

The E3 uses a sensor to measure the distance between the nozzle and the print bed at various locations to ensure optimal spacing for a higher success rate. This automatic leveling to different surface variations allows improved material adhesion to the bed and overall print quality. With the addition of the 9-point leveling system to the E3, substrate printing* now enables unlimited creativity on flat surfaces.

*The substrate printing is compatible with select materials and substrate types.

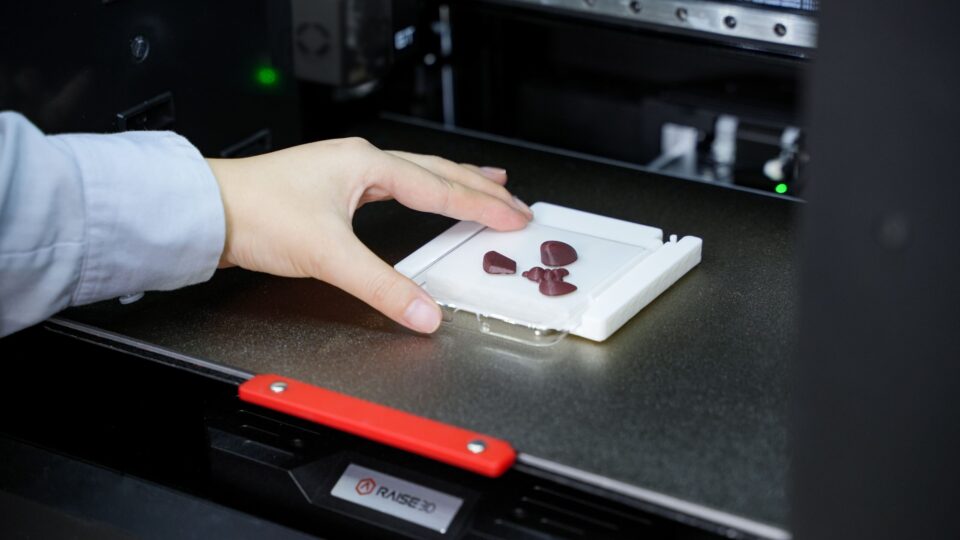

Substrate printing on a phone case, printed on the E3

According to Edward Feng, Raise3D’s Global CEO,

« The E3 redefines flexible material printing by merging versatility with performance. Building on the E Series legacy, it enhances the E2’s TPU printing capabilities and the E2CF’s composite filament printing expertise – now with notably faster print speeds and expanded material options. »

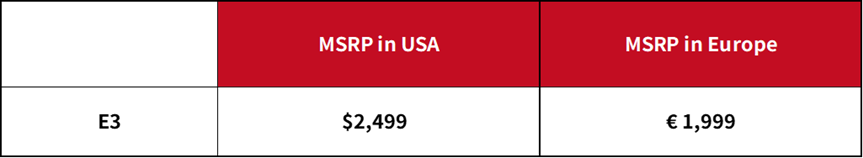

Availability and Pricing

The E3 is now available starting today, September 8th, 2025. Customers can take advantage of an exclusive special on all E3 orders placed between September 8th and September 30th, 2025. For more details on the E3 and the special offer, please visit here.

*Please note that the listed prices apply to the US and Europe markets. Pricing in other regions may vary.