What is a composite material?

Thermoplastics are popular 3D printing materials due to their stable chemical properties when heated. They can be easily melted, extruded layer by layer, and cooled to form models. However, thermoplastics generally have a low melting point and are not strong or rigid enough to make items that require higher strength. Composite materials have been applied to the field of 3D printing to produce mechanically more resistant pieces. Compared with traditional thermoplastics (such as ABS or PLA), composite materials are stronger, stiffer, more heat resistant and durable, effectively expanding 3D printing’s range of applications.

Composite materials are usually made by mixing two or more materials, such as polymer, non-metallic, or metal materials. When these materials are mixed, they retain their material characteristics and present new features that the materials did not have previously. The most commonly used composite materials in 3D printing are fiber-reinforced composite materials, namely carbon fiber, Kevlar, glass fiber, etc. Figure 1 compares the mechanical properties of composite materials to other materials.

Figure 1 Comparison of properties of composite materials and other materials.

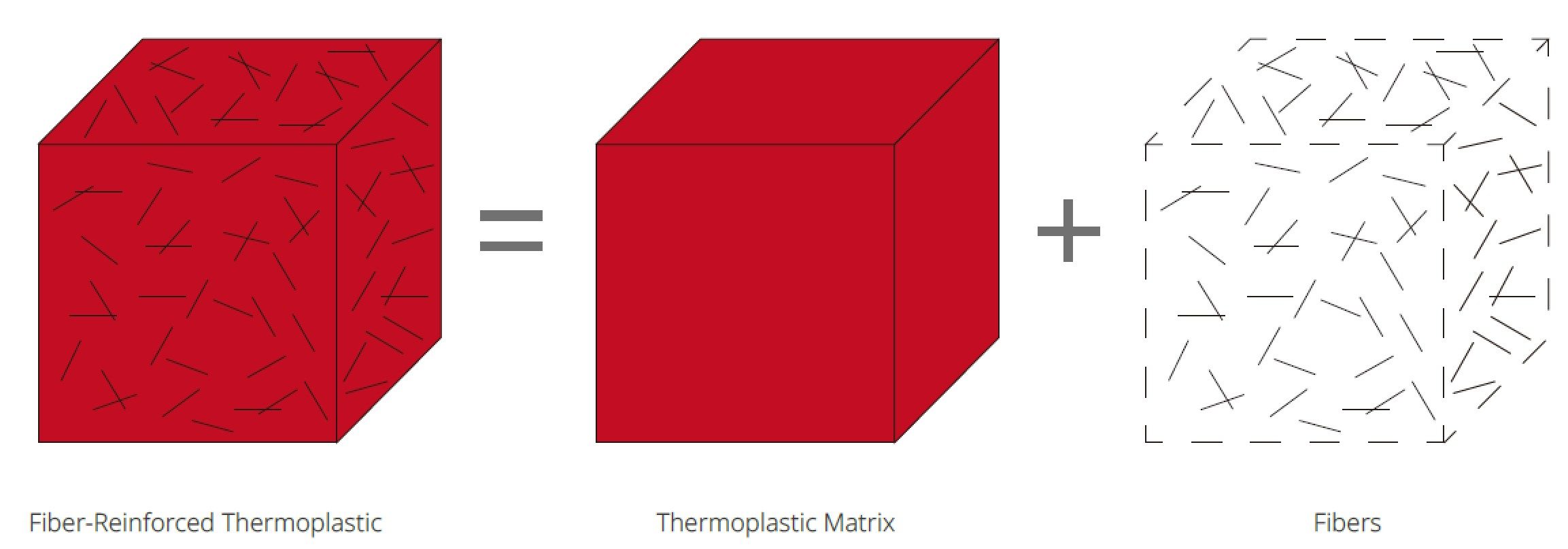

A fiber-reinforced composite material is composed of a base matrix and reinforcing fibers (as shown in Figure 2). The matrix is the core of the composite material, and the reinforcing material can significantly enhance the material’s performance. It can be a fiber, a granular, or a dispersed filler. But the fibers themselves are as brittle as spaghetti and easy to break, so they are usually wrapped or weaved within the matrix material to form a new material and exhibit the properties of both the matrix and the reinforcing material. In the context of 3D printing, the fiber-reinforced composite material can take two different forms: chopped fibers and continuous fibers.

Figure 2 The fiber-reinforced composite material is composed of a thermoplastic matrix and reinforcing fibers.

Chopped fibers are fibers cut to pieces less than 1 mm in length and then mixed into traditional thermoplastics to form filled plastic particles. These particles are further mixed and extruded into filaments that can be applied to FDM 3D printers. Usually, nylon or ABS is used as the base material for chopped fibers.

Continuous fibers adopt another different material mixing method, which is carried out simultaneously during the 3D printing process. The printer usually has two printing nozzles, extruding thermoplastic as the matrix material, and the long fiber coated with curing agent is heated and extruded through another auxiliary nozzle. The long fiber is fused with the thermoplastic matrix to directly print the model. This process is called Continuous Fiber Fabrication (CFF). CFF is where long fibers are wrapped in a thermoplastic or resin material and evenly distributed on each layer of the 3D printed model, similar to sandwich biscuits.

Figure 3 The structure of the continuous fibers.

Advantages and disadvantages of continuous fibers

Continuous fibers can absorb and distribute the stress along the entire length when being stretched or bent over. The reinforcement materials such as fibers are wrapped in a thermoplastic matrix so that the entire filament can withstand higher loads and absorb greater impact. The filaments have higher mechanical properties, achieving similar strength to aluminum with excellent strength and impact resistance. Models printed with composite materials are much lighter than models made with aluminum and other metals. Figure 3 shows the physical properties of carbon fiber and glass fiber compared with steel.

Figure 4 Comparison of physical properties between carbon fiber, glass fiber and steel.

When printing a model, you can place continuous fibers layer by layer in a specific area of the model (such as the tip and base of the model), thereby enhancing the model’s performance in that area. This is one of the main advantages of continuous 3D printing composite materials over chopped fiber materials. You can also choose different thermoplastic matrix materials (such as nylon, ABS, or PLA) according to your needs. It will achieve different material characteristics of the model from various aspects, such as better surface finish and higher printing accuracy.

However, continuous fibers also have some disadvantages. First, the filament’s strength cannot be enhanced vertically. The process of Continuous Fiber Fabrication (CFF) adopts a „sandwich-like” fusion method, affecting the bonding force between layers in the vertical direction of the model. Secondly, the model’s small features cannot be covered with continuous fibers, making that area’s strength lower than other areas, meaning the overall strength of the model is not evenly distributed. Thirdly, because the matrix fiber is wrapped in thermoplastic, some of its characteristics will be below the surfqace. For example, reinforced carbon fiber filament is wrapped by a thermoplastic or thermosetting resin, so a user cannot take advantage of the unique conductivity of carbon fiber . The abrasion resistance of the wrapped thermoplastic is lower than that of carbon fiber. Finally, Continuous Fiber Fabrication (CFF) requires multiple nozzles and spools of filaments, greatly increasing the cost of equipment and material.

Advantages and disadvantages of chopped fibers

Chopped fibers are usually ground or chopped into short fibers with a diameter of 5-10 microns and a length of 50-250 microns, which are mixed with other thermoplastic materials and processed into a uniformly-mixed composite fiber bundle. Different suppliers mix reinforcing fibers with different specific gravities into their plastics to produce filaments with different strengths. For example, reinforced carbon fiber accounts for 5-35% of the total weight. Since chopped fibers are created by a uniform mixing of reinforcing fibers and other thermoplastic materials, they are more uniform and have more stable characteristics. For example, the strength, rigidity, durability, and heat resistance of chopped fiber can be steadily improved. Figure 4 shows the reinforced carbon fiber taken at close range.

Figure 5 A close-up of chopped carbon fibers used in 3D printing.

As the reinforcing fiber is uniformly mixed with other thermoplastic materials, its strength and rigidity will improve. The overall model printed with this reinforced fiber filament will become stronger and more rigid. Mixing reinforcing fibers with low-performance materials can improve the overall mechanical properties of the filaments, increasing the resistance to stress of the model.

For example, the mixture of carbon fiber and thermoplastic can increase the thermal stability of the model. Because carbon fiber has a low coefficient of thermal expansion, it can effectively reduce warpage during printing. The carbon fiber can also help the printed models resist high-temperature environments and prevent deformation of the model.

Chopped fibers include other advantages. For example, chopped fibers are more wear-resistant. The chopped fiber has an improved wear resistance because it is a homogeneous mixture of the matrix material and reinforcing material.

Secondly, chopped fiber retains the characteristics of a variety of materials. For example, carbon fiber can ensure the overall conductivity of the model that requires conductivity. Carbon fiber has higher wear resistance because the externally worn part becomes graphite, which protects the friction surface and reduces the friction coefficient.

When printing with chopped fibers, the details of the model can also be evenly covered by chopped fibers to ensure the overall characteristics of the model.

A special 3D printer is not required to print chopped fiber. It can be printed on any FDM printer.

It is important to know that carbon-fiber filament usually only contains 5-35% of carbon fiber. Filaments become rough if they contain too high carbon fiber, and the surface finish of the model will be rough. Using filament containing too much carbon increases the risk of jamming and extruder component wear during the printing process.

Raise3D creates a new choice for carbon fiber printing

Raise3D has launched the E2CF, a professional desktop printer for printing carbon fiber reinforced filament, and has also released a dedicated carbon fiber PA12 filament to use with top filament manufacturer BASF. E2CF uses a highly wear-resistant nozzle and feed system. The extruder and nozzle have enhanced function and machinery. Users can print parts with high quality, wear-resistance, and higher mechanical properties with PA12 CF filaments. Resulting models have an excellent surface finish and almost no post-treatment is required. All these features make PA12 CF an ideal choice for fixtures, engineering tools, and various industrial end-use parts.

Now that you have learned the basic knowledge of composite materials, you also understand the advantages and precautions of chopped fibers and continuous fibers commonly used in 3D printing. You can choose the corresponding filaments and printing methods according to your needs when printing the model. Not only can you get a stronger model with higher mechanical performance, but you can also expand your understanding of composite materials so that you can choose more suitable materials in the future printing process.