Release notes

New requested features and debugging based on user feedback.

New Features

· Slice Settings

1. Added option to print shells in optimal order to reduce travel moves.

For example, before moving from one hole to another, the shells of one hole will be completed first instead of printing all the outer shells of all holes first then start printing inner shells.

2. Added seam hiding options to place the start point on the corner.

You can choose to place the start points at the reflex or convex corner of the outer shell.

If the angel of two edge lines at corner is larger than 180 degrees, the corner is a reflex corner. Otherwise, it is a convex corner.

3. Avoid placing the start point at overhang sections in each layer.

4. Added option to set the minimal length of each single extrusion line.

5. Added option to merge the two nearby lines to be one.

6. Added option to set XY compensation for outer contours and holes.

You can set different compensation values for contours and holes. Negative value will decrease the size of contours and holes of objects in each layer.

7. Added option to print infill structure before shells.

8. Added option to only enable Z Hop when printing solid fill sections.

Enabling this option will trigger Z Hop only at the top or bottom solid layers which will reduce quantity of Z Hop and avoid the effects of nozzle traveling above the printed solid sections which can help leave a cleaner solid surface.

9. Added option to place coasting on Grid Pattern Infill and Lines Pattern Solid Fill.

10. Added option to wipe the nozzles at the end of loop of the outer shell.

Adding an extra travel path at the end of the outer shell is helpful to reduce Z-seam scars. You can set the distance of the travel path and the traveling speed.

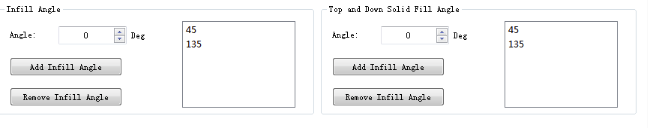

11. Added option to set interlaced infill angle for infill structure and solid fill parts.

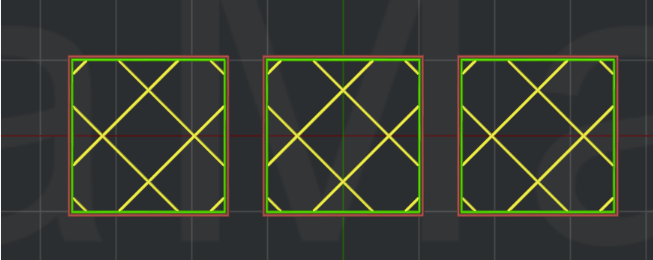

12. Added option to print infill once each several layers.

Multiple layers of infill will be merged and printed once each several layers. It will help to reduce printing time.

13. Added option to fill the solid parts with gap filling if the parts are failed to be filled by Lines, Rectilinear or Concentric pattern.

The narrow solid sections sometimes will be failed to be fully filled with the selected solid fill pattern. With this option enabled, the software will use gap filling to fill the narrow sections.

14. Added option to define infill patterns for top and bottom solid parts separately.

15. Added option to unify the infill structures for multiple isolated models.

Every infill structure will be aligned to same origin and offset for multiple isolated models.

16. Added more settings under Raft – Raft Infill Angle, and Raft Flow Rate.

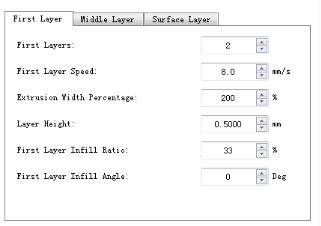

17. Added option to print outer shell first after Brim for the first layer.

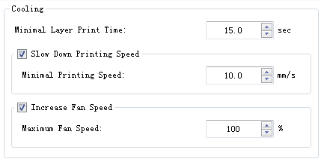

18. Added option to drop the printing speed and increase fan speed for the layers with shorter layer printing time compared with minimal layer print time.

If the current layer printing time is shorter than the defined minimal layer print time, you can opt to enable printing speed and fan speed auto-tuning. The printing speed will be reduced to increase the layer printing time and the fan speed but not exceed the maximum fan speed.

19. Added option to blip fan speed to 100% when starting from a low fan speed.

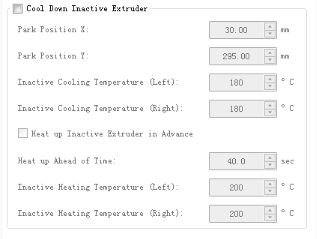

20. Added option to cool down inactive extruder.

Cool down the inactive extruder during printing to prevent oozing. The nozzles will move to the park position to wait until the next printing nozzle reaches to the target temperature.

What’s more, you can choose to heat up the inactive extruder to some temperature in advance to reduce the waiting time.

21. Added option to override filament settings for the right extruder only.

22. Added option to force retraction before moving to outer shell.

23. Added option to enable retraction at defined top and bottom layers even Avoid Retraction Inside Models is enabled.

24. Added option to limit the length of travel path while traveling around the holes.

25. Added option set the speed of printing Wipe Wall and Wipe Tower.

26. Added option to set the position of Wipe Tower.

27. Added option to enable/disable bridging detection.

28. Improved bridging detection and added option to set fan speed when printing bridging, fixed bridging angle and minimal bridging allowed area.

29. Added option to choose the preheat sequence in Start GCode.

30. Added option to reset global flow rate to 100% in End Gcode.

31. Added support for IF command for conditional statements in Extruder Switch GCode, Layer Change GCode, Retraction GCode.

32. The build plate will be dropped before moving the nozzle in XY direction during layer change.

33. Disable thin wall detection by default once Vase Mode enables.

34. Added checking for travel paths to make sure not travel through holes before starting printing the next layer.

35. Added slicing settings information in gcode files.

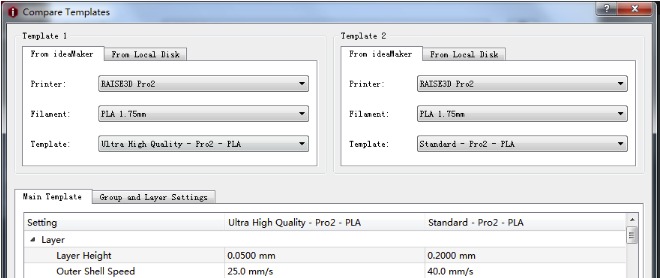

36. Added a function to compare the differences between two slicing templates.

You can choose two slicing templates to compare the difference under Slice – Compare Templates, Slice – Manage Templates or Start Slice – Compare.

ideaMaker supports comparing .data files or .gcode files which contain slicing settings information as well.

37. Added support for directly editing values in table sheets for infill angle, support infill angle, temperature control list, fan speed list and pause height list by double clicking.

38. Added Wipe Tower Fill Ratio into Per-Layer Settings.

You can set different infill ratio values for different heights of Wipe Tower.

39. Speed Multiplier setting under Per-Layer Settings is now also applied to gap filling speed and single extrusion filling speed.

40. Added support for restoring every slice setting separately for default slicing templates.

41. Added support for changing slice settings overridden by filament settings directly in Edit Template and Advanced Settings.

42. Improved slicing settings for Raise3D Pro2-series printers.

· User Interface

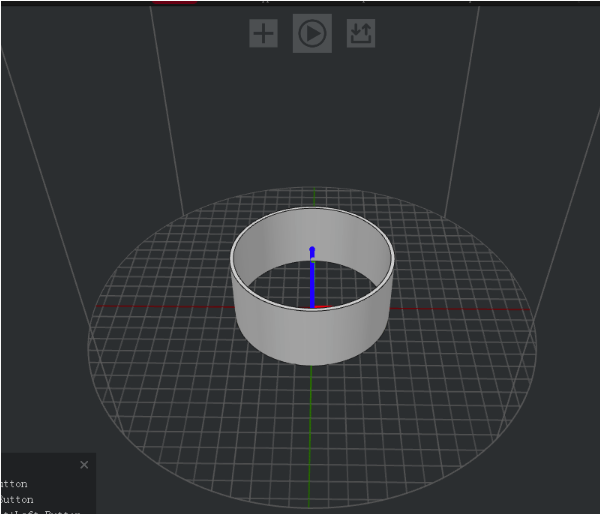

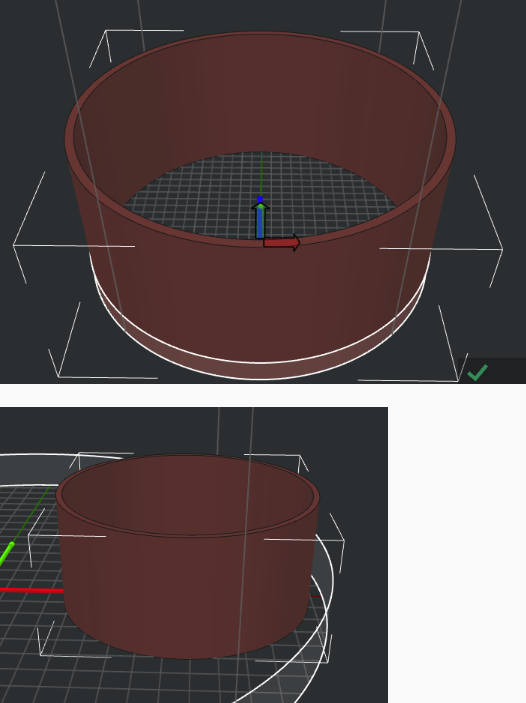

43. Added support for circular build plate.

You can set circular build plate under Printer Settings.

Note, when current printer is selected as a circular build plate type, Max Fit and print boundary checking will be based on the outer surface of objects instead of bounding box.

44. Added option to set the firmware type of printers.

45. Added option to omit outputting RaiseTouch-specified gcodes for third-party printers and you can specify other gcodes to overwrite default commands.

46. Added importing and exporting printer settings from local disk with .printer file.

47. Added option to reset the printer settings to be default settings.

48. Added option to set the separate diameter for right extruder under printer settings.

49. Added virtual offset to check whether models are outside of the extruder’s printing range while both extruder offset X and Y are 0.

50. Added option to set the safe distance from the border of the build plate.

51. Added the temperature control list, fan speed list and pause height list into Override Slicing Settings under Filament Settings.

52. Added option to save notes under filament settings.

53. Added option to set filament brand and display name under filament settings.

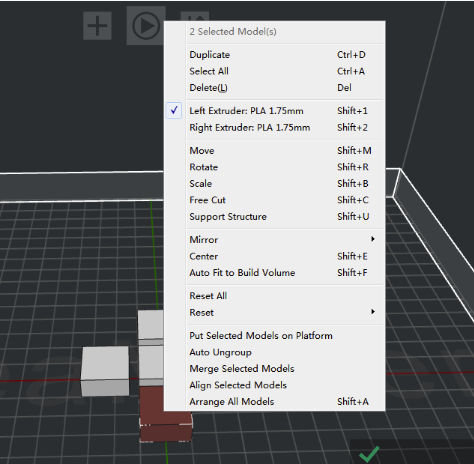

54. Added a context menu.

Left click to select and right-click on models to see the menu which includes model transformation, cutting, manual support, arrange and select the extruder printing the models.

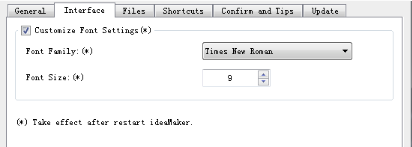

55. Added option to customize font family and font size under Interface in Preferences.

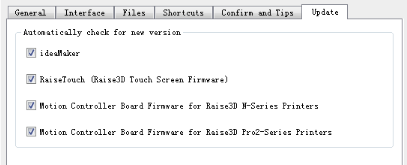

56. Added option to turn on or off the update notification of Raise3D touch screen firmware (RaiseTouch) and motion controller board firmware (N-series and Pro2-series both) in Preferences.

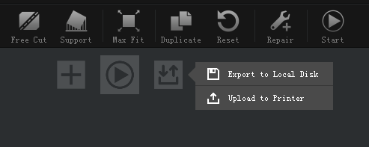

57. Added Export function to Upload button export files to local disk in the main interface (the third icon placed at the top of main interface).

58. Auto-save the last selection of unit (inch or mm) in the side panel of main interface.

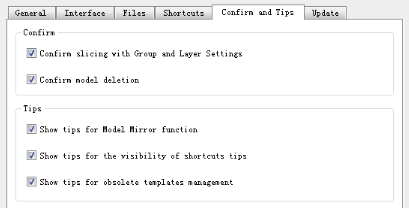

59. Added option to turn on or off the notifications of confirmation and tips for slicing with Group and Layer Settings, model deletion, model mirror function, etc.

60. Changed grid size to 10mm in main interface.

61. Added German Language.

· Remote Connection

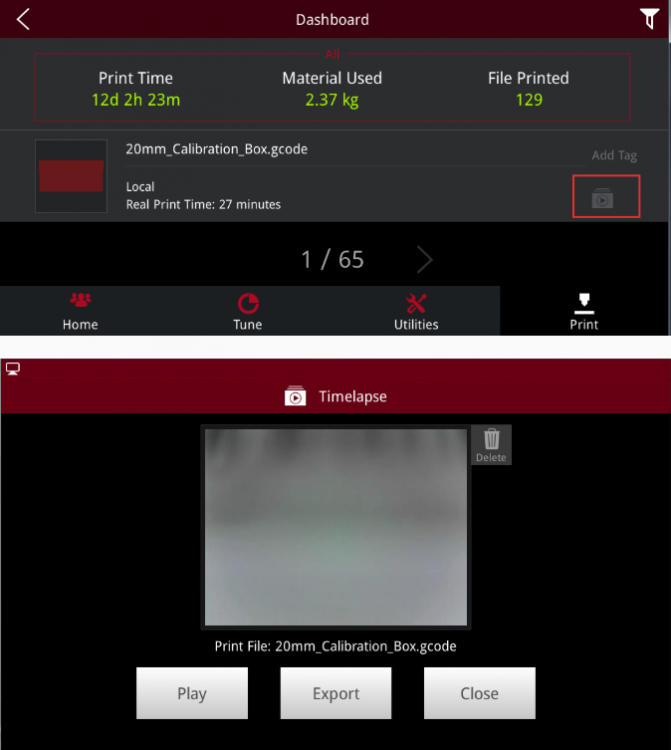

62. Added support for viewing and exporting timelapse of completed print task in Dashboard under Remote Connection (RaiseTouch 1.0.0 or newer is required).

63. Added the camera shot button in the camera view under Remote Connection.

64. Added support for incognito mode under Remote Connection.When the connected printer is in incognito mode (RaiseTouch 1.0.0 or newer is required for incognito mode).

You cannot use camera function in ideaMaker when the printer is in incognito mode,

· Bug Fixes

65. Fixed Wipe Wall generated incorrectly across different setting groups issue.

66. Fixed the issue that the retract incorrectly with Avoid Retraction Inside Models and Avoid Traveling Through Holes both enabled.

67. Fixed issue that dense support is not expanded correctly following the value of Horizontal Expansion.

68. Fixed the issue that the temperature settings in filament settings do not override the settings during slicing.

69. Fixed the not highlighted selected models issue in project list.

70. Fixed issue that the model preview is generated incorrectly in .data file if some parts of print are under the build plate.

71. Fixed display issue under High-DPI display at Linux system.