Reading Time: 23 Minutes

When we talk about the “strength” of resin 3D prints, we’re not just talking about one number.

Strength can mean tensile, flexural, compression, impact, or even shear resistance—and each reacts differently depending on the resin chemistry, how you design the part, and how well you cure it.

Standard photopolymer resins are often brittle, but once you step into engineered, tough, ABS-like, or composite families, the numbers change fast.

Tensile strength can more than double, climbing from 20–30 MPa in basic resins to 70–90+ MPa in engineered blends.

Composite and rigid resins push flexural strength into the 130–170 MPa range, making them competitive with or stronger than many filament printing materials.

For context, PLA averages 28–50 MPa, ABS around 32 MPa, and PETG about 40–60 MPa. FDM still leads on impact toughness, but tough resin formulations close the gap.

The good news is, you can make simple choices that boost performance right away: pick a tougher or engineering resin, add wall thickness and fillets to spread stress, orient parts with the load path, and dial in curing so you don’t end up with weak cores or brittle shells.

Today, brands like Raise3D with its Rigid 3K, Standard White, High Detail, and ESD resins, Liqcreate with composite solutions, Formlabs with specialty families, BASF Forward AM for industrial grades, Elegoo for ABS-like blends, and Loctite for medical or ESD needs all give you options tailored to specific applications.

In this article, we’ll focus on what really drives resin strength, how it stacks up to filament, and what you can do to unlock the full potential of your resin prints.

How Strong are Resin 3D Prints?

Standard resin materials often measure between 20 and 50 MPa in tensile data, which works for light prototypes but can feel brittle in daily handling.

Tough or engineering grades raise tensile into the 55–90 MPa range, giving you more reliable results for fixtures, housings, and snap-fit parts.

Flexural strength shows a similar spread: standard resins deliver about 50–60 MPa, while engineered types hold between 80 and 100 MPa. Composite or ceramic blends can reach 150–170 MPa after proper uv and thermal cure, placing them closer to injection molding plastics in bending performance.

Impact numbers highlight the difference between rigidity and toughness. A rigid resin with high stiffness may show only 17–20 J/m on a notched Izod test, which means it resists bending but can chip under shock.

Tough or ABS-like blends absorb more energy, often 41–48 J/m, and trade a little stiffness for elongation and crack resistance. Compression strength ranges from about 68–72 MPa for rigid resin to 158 MPa for composite-reinforced systems, which is useful when you print jigs, clamps, or fixtures that need to resist squeeze forces without deformation.

Shear values generally follow tensile trends, making tough grades better suited for clips, gears, or parts with sliding contact.

For perspective, PLA filament often sits between 28 and 50 MPa tensile, ABS around 32 MPa, and PETG about 40–60 MPa. That means resin prints, with the right material and cure, can match or even surpass these plastics in tensile and flexural strength.

The trade-off is that brittleness remains a risk unless you choose a tough family and design with stress diffusion in mind.

With these benchmarks in mind, the next question is natural: how do these resin numbers stack up against filament printing like PLA, ABS, and PETG in day-to-day use?

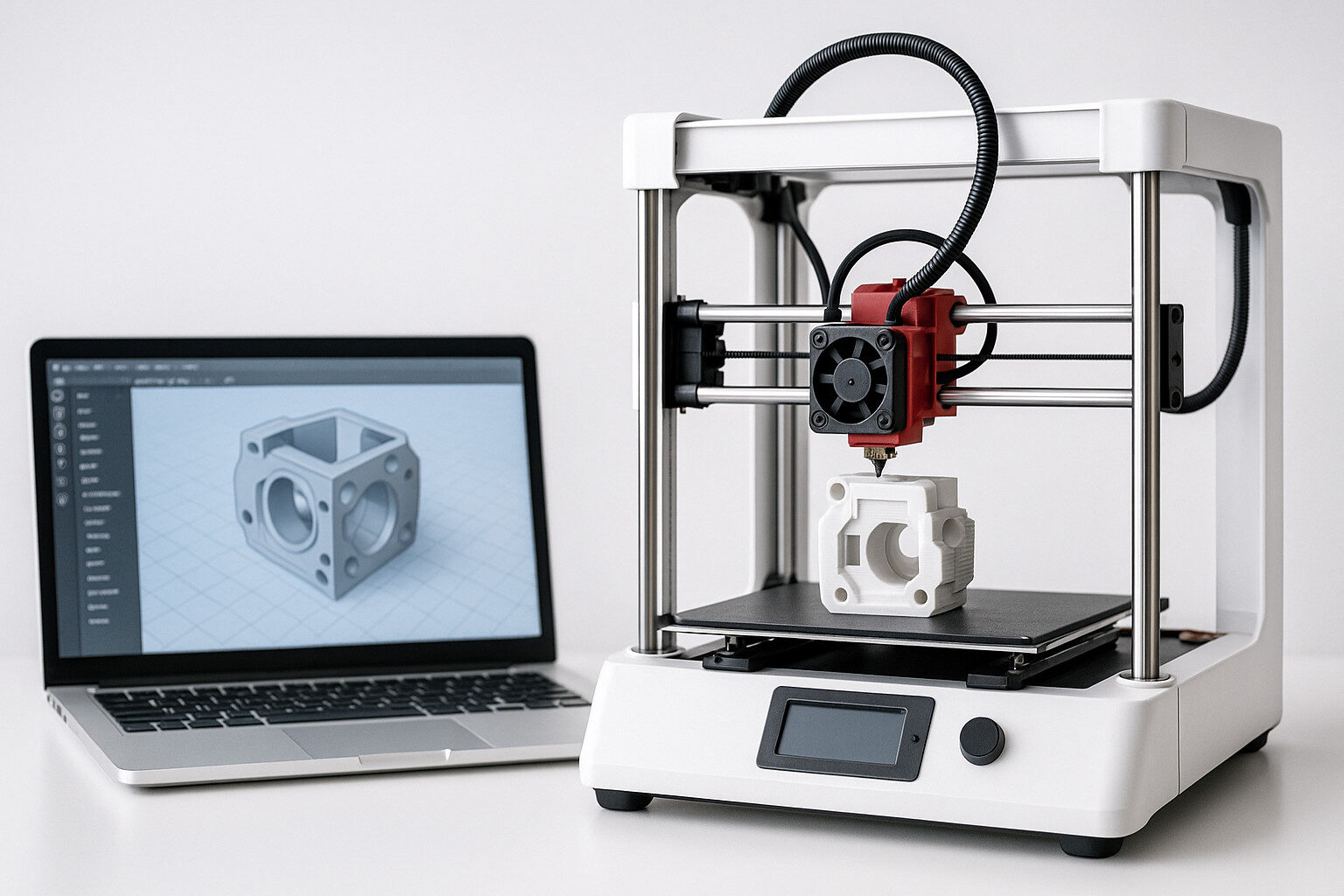

How Does Resin Compare to Filament in Strength?

On tensile strength, PLA ranges between 28 and 50 MPa, ABS sits near 32 MPa, and PETG falls around 40–60 MPa. Engineered resin prints typically reach 55–90 MPa, which means resin can outperform filament when resisting pulling forces.

Flexural strength tells a similar story, with high-performance resins exceeding 130 MPa and composites reaching 150–170 MPa after thermal cure, numbers that surpass many FDM plastics in bending stiffness.

Impact strength is where filament printing often leads. ABS, nylon, and certain PETG grades can take repeated shocks that brittle resins cannot.

Tough resin narrows the gap with values of about 41–48 J/m, but standard rigid resin remains behind in impact-heavy scenarios. Another important difference is isotropy versus anisotropy.

Resin parts cured by sla, dlp, or lcd methods are more isotropic because light crosslinks the entire layer, giving you consistent properties across axes. Filament prints depend on layer adhesion, which can weaken the Z direction and create anisotropy in results.

For real-world applications, FDM is the better solution for living hinges, repeated impacts, and large flexible pieces. Resin wins when you need surface finish, accuracy, small functional pieces, and snap-fits that demand high flexural strength.

Comparison is helpful, but decisions live in the real world, so are resin prints actually strong enough for functional parts under load, heat, and repeated use?

Are Resin 3D Prints Strong Enough for Functional Use?

Yes, resin prints can be strong enough for functional use, but only when you match the material and design to the purpose. If you rely on standard 3d printing resin, you will get brittleness that limits parts to decorative models, display pieces, or miniatures.

These prints can achieve surface finish and accuracy, but they fail quickly under repeated stress or impact.

For duty applications where you need mechanical reliability, you should look at tough or engineering grades that measure around 55–90 MPa in tensile strength and more than 100 MPa in flexural performance.

The difference shows up in real-world parts.

Snap-fits, hinges, and small jigs built from engineering resins can hold up to functional loads, while composite blends with high compression strength around 158 MPa excel in rigid tooling.

Outdoors or in heated locations, a standard sku will deform or crack, but high-temp or UV-resistant resins maintain resistance under those conditions.

If your 3d printer uses SLA or DLP technology, curing protocols and resin compatibility with the equipment also decide whether a product is safe for service.

Before using resin prints in a demanding case, confirm values with ASTM or ISO tests, review the material data from the manufacturer’s page, and make sure your design minimizes sharp corners or stress concentrations.

What Factors Influence the Strength of Resin 3D Prints?

The strength of resin prints is not fixed but shaped by several co-equal levers that you control during 3d printing.

- The first and most important is the material family you choose, since standard resin will always be weaker than tough, engineering, or composite grades.

- Design decisions matter almost as much: wall thickness, fillets, and geometry help diffuse stress and reduce shrinkage cracks.

- Printer settings add another layer, where orientation, layer height, and exposure define how the object bonds across layers.

- Post-processing is equally critical, if you skip proper wash and cure, you leave “green” interiors with low resistance, while over-curing can make surfaces brittle.

- Environmental conditions, from uv exposure to heat and chemical contact, slowly change resin properties and shorten service life.

- Stress concentrators such as sharp corners or thin ligaments act as weak points that lower compression strength and impact resistance.

- Even support structures play a role, because poorly placed supports create scars and stress risers that weaken final prints.

How Do Resin Types Affect Strength?

Different resin types each bring a distinct combination of benefits and limitations, and knowing these differences helps you pick the right sku for your application.

Tough or ABS-like grades trade some stiffness for better impact performance, often reaching 41–48 J/m on notched Izod while holding tensile strength around 40–70 MPa.

These resins are ideal for snap-fits and functional pieces that need resistance to cracking. Engineering or rigid blends shift the balance toward stiffness, with tensile values between 55–90 MPa and flexural properties above 130 MPa. They resist bending well but can chip under shock, so you use them where accuracy and stiffness matter more than impact.

Composite-reinforced families stand at the high end, achieving flexural strengths of 150–170 MPa with thermal cure and compression strength close to 158 MPa.

These are best for jigs, tooling, and structural parts where deflection cannot be tolerated.

Flexible resins, often rated at about 80A Shore, show very low tensile strength in the 4–9 MPa range but compensate with elongation above 100% and high tear resistance, making them perfect for seals or cushioning pieces.

Biocompatible resins maintain performance close to engineering baselines while passing ISO standards for cytotoxicity and skin contact, useful for dental and medical equipment.

Specialty types such as high-temp, ESD, or chemical-resistant blends are tailored for specific environments. Once you’ve picked a material, geometry takes over, your fillets, ribs, wall thickness, and transitions decide where cracks start or stop.

How Does Design Impact Resin Print Strength?

Design decisions strongly influence how resin prints handle stress, and small changes in geometry can make the difference between a fragile piece and a reliable product.

Wall thickness is the starting point: you should keep most parts at least 1–2 mm thick, while unsupported walls need no less than 1 mm.

Hollow designs work well to save material, but walls should remain around 2 mm to preserve stiffness and prevent collapse under compression strength.

Sharp corners act as stress risers, so adding fillets or chamfers diffuses loads and reduces crack initiation. Inside radii of 0.5–1.0 mm are usually enough to curb brittleness. Ribbing and gussets are another design tool, providing reinforcement without adding mass.

By aligning ribs with expected loads, you increase flexural resistance and overall stiffness.

Hollowing requires careful placement of drain holes. Without them, trapped 3d printing resin can build pressure, leading to cracks or failed curing.

Place holes away from load paths and in locations that simplify cleaning during post-processing.

For example, if your 3d printer uses SLA or DLP, good resin compatibility with the wash station and curing equipment ensures consistent results.

Orientation ties everything together, so let’s tune layer height, exposure, orientation, and peel to protect interlayer bonding and accuracy..

How Do Printer Settings Affect Strength?

Printer settings define how resin cures layer by layer, and even minor adjustments can shift performance.

Layer height is one variable: thinner layers may improve bonding across the object, while thicker layers sometimes increase bulk strength. The only way to confirm is by testing coupons with your chosen material.

Exposure settings are equally important. Under-exposed layers weaken interlayer crosslinking, but over-exposure can embrittle surfaces and reduce accuracy.

Always calibrate by resin type and cure under the manufacturer’s data. Orientation also plays a key role, align features with load vectors and reduce peel stress on critical faces.

If your slicer supports lattice infill, denser cores raise stiffness but complicate washing and curing. Default hollow or solid prints remain common.

Finally, monitor lift speeds and delays. Aggressive movements during printing can cause micro-cracks or delamination in tall or thin pieces, lowering both flexural and impact resistance.

Settings get you close; however, post-processing locks in performance, washing, curing, and careful support removal can make or break final strength.

How Do Post-Processing Steps Affect Strength?

Post-processing is one of the most decisive stages in 3d printing resin, because every step, support removal, washing, and curing, shapes the final performance of resin prints.

If you clip supports too early or at the wrong angle, you create gouges that act as stress concentrators. Waiting until after full cure reduces denting and micro-cracks, especially on delicate features.

Washing comes next, and here you remove uncured resin from the surface and internal cavities. Using IPA is common, but alternatives like TPM can lower brittleness risk and avoid excessive shrinkage.

Incomplete washing leaves a weak skin that reduces compression strength and flexural resistance, weakening the part during duty applications.

Curing is where properties reach their intended level. Correct UV wavelength, intensity, and time raise tensile and flexural strength, but if you under-cure, the part stays soft and weak.

Over-curing does the opposite, producing brittle surfaces and poor impact results. Thick objects or composite grades often need staged or thermal cure to complete the chemical conversion.

How Do Environmental Factors Affect Resin Print Strength?

Even strong resin parts lose performance when exposed to harsh environments. UV from sunlight accelerates embrittlement and discoloration, but coatings or pigmented UV-stable materials help maintain resistance.

Heat is another challenge. Standard resins soften around 50–60 °C, so you need high-temp or engineering blends for applications near equipment that generates heat.

Moisture and chemicals also degrade properties over time. Composite and engineering resins offer better resistance, but you should confirm compatibility with exposure charts provided on the manufacturer’s page or website.

Outdoor weathering combines all of these factors, leading to micro-cracks, surface finish changes, and color shift.

How Does Stress Concentration Affect Resin Print Strength?

Stress concentrations are weak points that form around abrupt changes in design. Sharp corners, thin ligaments near holes, or sudden shifts in wall thickness create local spikes in load that shorten part life.

To reduce risk, you should add fillets of at least 0.5–1.0 mm at inside corners and taper transitions between thick and thin sections.

Holes should be placed with generous edge distances, at least twice their diameter when in thin walls.

This prevents cracks from initiating at unsupported material. Support contact points also matter; when they sit on high-stress areas, they leave scars that become failure sites.

By moving them to low-load regions or blending them during post-processing, you help maintain compression strength, flexural resistance, and overall durability.

What Role Do Support Structures Play in Print Strength?

Support structures in 3D printing resin are essential for successful prints, but they directly influence strength and surface finish.

Supports prevent warping and delamination during the peel process, yet they act as local stress raisers where they touch the resin.

To balance print success with durability, you should avoid placing heavy supports on critical faces or load paths.

Smaller tip sizes work better on cosmetic or high-stress areas, since they leave smaller nubs that can be blended with sanding or coated for smoother results.

Density and orientation also matter. Orienting the object so that supports attach to low-stress zones reduces weakness in functional parts.

Adding fillets where supports meet the base can minimize stress during removal. Timing of removal is equally important, taking supports off after a full cure helps brittle resins avoid gouges or cracks.

Support strategy depends on process physics, so how do SLA lasers versus DLP/LCD projectors affect cure uniformity and properties?

How Do SLA, DLP, and LCD Processes Influence Strength?

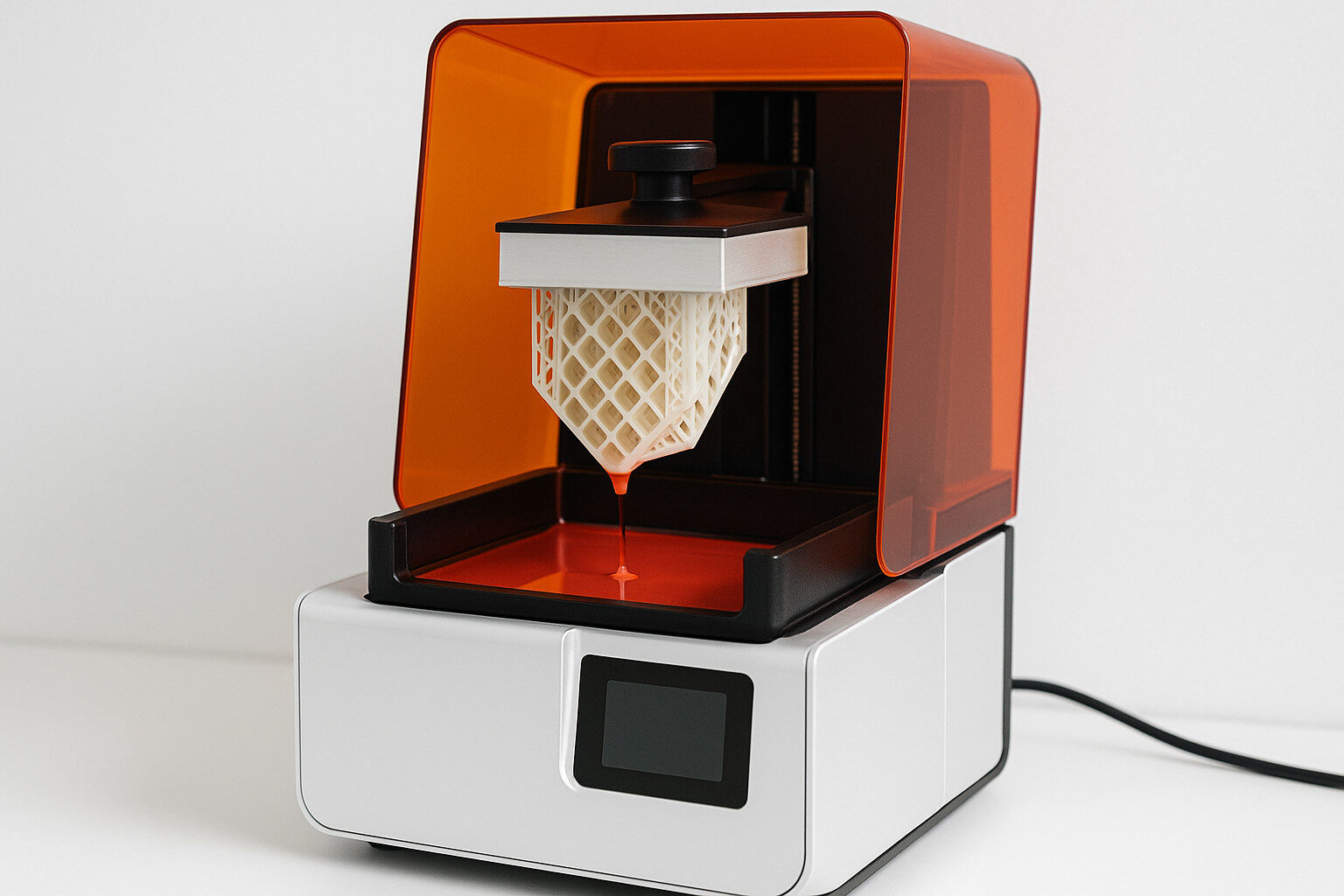

All vat-based 3d printers cure resin layer by layer with light, but the way light is delivered changes performance details.

SLA uses a laser trace to cure each point, which provides very high precision and is ideal for fine features where stress concentrators must be minimized. The trade-off is slower speed compared to other methods.

DLP projects a full image at once, while LCD masks light through a panel, making both faster for larger duty applications. Resolution depends on pixel pitch, which in turn influences surface finish and accuracy.

Strength differences between these processes are less about the printer type and more about resin compatibility, cure settings, and material properties.

Uniform illumination in DLP and LCD can provide consistent crosslinking across a layer, which improves flexural stiffness and overall performance.

SLA excels in cases that demand accuracy, while DLP and LCD often deliver efficiency for production runs.

How Is Resin Strength Tested?

The benchmark numbers you see for resin prints come from standardized tests that measure mechanical properties under controlled conditions. Tensile strength is usually determined with ASTM D638 or ISO 527 dog-bone specimens, where results are reported in MPa and percent elongation.

Flexural strength comes from ASTM D790, a three-point bend test that shows how the material resists bending, expressed again in MPa along with modulus values.

Impact resistance is often measured with ASTM D256 (notched Izod), reported in J/m, giving you a clear sense of how resin prints absorb shock. Compression strength is tested with ASTM D695, yielding MPa data such as ≈68–72 MPa for rigid resins or ≈158 MPa for composite systems. Elastomeric types are checked for hardness using Shore durometer scales, often around 80A.

What are the Strongest Resin Types Available?

Composite-reinforced resins lead for stiffness, with flexural values of 150–170 MPa after thermal cure and compression strength near 158 MPa, making them ideal for rigid tools and fixtures.

Engineering or rigid resins follow, delivering tensile performance around 55–90+ MPa and flexural strength above 130 MPa, which makes them strong candidates for snap-fits or enclosures.

Tough or ABS-like blends emphasize impact resistance, reaching 41–48 J/m on a notched Izod test, while still maintaining tensile values of 40–70 MPa. Flexible resins operate differently, showing Shore 80A hardness and elongation above 100%, giving them shock absorption for seals or cushioning parts.

Specialty families, like high-temp, ESD-safe, or chemical-resistant, focus more on environmental compatibility than raw MPa numbers, but they extend the duty applications of resin prints into demanding conditions.

What Strong Resins are Currently Available on the Market?

The market for strong 3d printing resin includes high-performance options that rival or surpass traditional plastics in tensile, flexural, and compression strength. Raise3D offers engineering-grade resins tuned for stiffness and accuracy, while Liqcreate Strong-X is a benchmark product in rigid performance. Each has clear strengths and trade-offs depending on your application.

Raise3D Rigid 3K Resin

Raise3D Rigid 3K Resin delivers engineered strength and heat resistance for demanding duty applications. It competes directly with leading composite-class materials while maintaining high accuracy and stable surface finish. You can view full specifications on the Raise3D Rigid 3K Resin page.

Key properties:

- Tensile Strength: 78 MPa

- Flexural Strength: 139 MPa

- Impact Resistance: Notched Izod 30 J/m

- Heat Deflection Temperature: 97 °C

Best for:

- Jigs and fixtures requiring stiffness

- Structural housings and enclosures

- Functional prototypes exposed to heat

Limitations:

- Moderate toughness compared to ABS-like blends

- Less suitable for repeated shock or high-impact loads

Liqcreate Strong-X

Liqcreate Strong-X is a rigid engineering resin with excellent flexural performance, making it ideal where bending resistance is critical. Proper washing and extended post-curing maximize its mechanical properties, bringing it into the top tier for stiffness.

Key properties:

- Tensile Strength: ~52–70 MPa (up to ~84 MPa with extended cure)

- Flexural Strength: 121–130 MPa (can reach ~134–140 MPa)

- Impact Resistance: Notched Izod ~17–20 J/m

Best for:

- Jigs and fixtures under static loads

- Stiff housings with precise dimensions

- Functional prototypes that prioritize flexural strength

Limitations:

- Moderate impact toughness

- Requires thorough wash and post-cure to achieve full performance

Liqcreate Composite-X

Liqcreate Composite-X is a composite-reinforced rigid resin designed for extreme stiffness. Its values put it among the top performers for bending and compression strength, making it ideal for static structural parts.

Key properties:

- Flexural Strength: ≈150–170 MPa after UV + thermal bake

- Compression Strength: ≈158 MPa

- Tensile Strength: Up to ~85 MPa reported

Best for:

- Rapid tooling and rigid fixtures

- Aerodynamic models that need stiffness

- Applications where bending and compression dominate

Limitations:

- Impact toughness is only moderate

- Requires careful design with fillets and avoidance of sharp internal corners

Elegoo ABS-Like Resin

Elegoo ABS-Like Resin is a budget-friendly “ABS-like” material aimed at users who want more toughness than brittle standard formulations without paying premium resin prices. It balances accessibility with practical strength for general duty applications.

Key properties:

- Tensile Strength: ~30–52 MPa

- Flexural Strength: ~40–70 MPa

- Impact Resistance: Notched Izod ~41–48 J/m

Best for:

- General functional prints and prototypes

- Household replacement parts

- Entry-level resin printing projects requiring more toughness

Limitations:

- Lower heat resistance compared to engineered grades

- Still less ductile than advanced filament printing options

Formlabs Flexible 80A Resin

Formlabs Flexible 80A Resin replicates the feel of rubber, making it the go-to choice when you need elasticity and energy absorption instead of high stiffness. It delivers consistent performance across grips, seals, and cushioning pieces.

Key properties:

- Shore Hardness: 80A

- Elongation at Break: ~100–120%

- Tensile Strength: ≈3.7–8.9 MPa

- Flexural Strength: ≈31–39 MPa

- High Tear Strength: Color-dependent

Best for:

- Grips, seals, and ergonomic parts

- Cushions and shock-absorbing applications

- Prototypes simulating elastomeric materials

Limitations:

- Low tensile strength limits structural use

- Dimensional control can be more challenging than rigid resins

Liqcreate Deep Blue

Liqcreate Deep Blue is a rigid general-purpose resin that offers stable performance for functional prototypes. While not engineered as a “tough” resin, it provides dependable compression values for prints where dimensional accuracy and stiffness matter.

Key properties:

- Compression Strength: ≈68–72 MPa (post-cure)

Best for:

- Functional prototypes that must retain their shape

- General resin prints where stiffness and stability are required

Limitations:

- Not designed as a tough resin

- Susceptible to stress risers without proper design

Liqcreate Tough-X / Premium Tough / Clear Impact

This family of resins prioritizes elongation and impact resistance, making them closer to ABS-like materials than brittle rigid formulations. You gain flexibility in design, though at the cost of some tensile and flexural strength.

Key properties:

- Impact Resistance: Higher than rigid resins

- Elongation: Superior to standard blends

- Heat Resistance: Lower than composite or engineering grades

Best for:

- Snap-fits and parts exposed to drops or sudden shocks

- Prototypes that need some give and durability under stress

Limitations:

- Less stiff than rigid or composite resins

- Heat performance must be verified for demanding applications

BASF/Forward AM Ultracur3D Rigid RG35

BASF’s Ultracur3D Rigid RG35 is an engineering-grade resin designed to combine stiffness with moisture resistance. With balanced tensile strength and durability, it is particularly suited for enclosures and parts that need dimensional stability.

Key properties:

- Tensile Strength: ≈49 MPa (reported value)

- Stiffness: High for consistent performance

- Moisture Resistance: Better than many standard resins

Best for:

- Housings and enclosures in functional products

- Applications requiring stable dimensions over time

Limitations:

- Impact resistance is below tough resin families

- Less suited to parts expected to handle repeated shocks

Raise3D Standard White Resin

Although labeled as “standard,” Raise3D Standard White performs closer to an engineering resin. It provides balanced strength and rigidity while remaining accessible compared to composites. You can view full specifications on the Raise3D Standard White Resin page.

Key properties:

- Tensile Strength: 67 MPa

- Flexural Strength: 108 MPa

- Impact Resistance: Notched Izod ~33 J/m

- Heat Deflection Temperature: 77 °C

Best for:

- Prototypes and functional prints needing durability

- Engineering models requiring accurate flexural and tensile values

- Resin prints exposed to moderate heat or mechanical loads

Limitations:

- More rigid under shock compared to tough or elastomeric blends

- Less forgiving for repeated high-impact use

Formlabs Tough 4000

Formlabs Tough 4000 is a glass-reinforced resin that balances rigidity with controlled ductility. It resists deformation and is intended for functional prototypes and jigs that require stiffness but not extreme flexibility.

Key properties:

- Strength Profile: Tough/rigid balance

- Application Focus: Jigs, fixtures, functional models

Best for:

- Prototypes requiring stiffness and reliable load resistance

- Jigs where moderate ductility prevents brittle failures

Limitations:

- Impact resistance is lower than elastomeric formulations

- Not as stiff as composite-reinforced resins

B9Creations BioRes

B9Creations BioRes is a biocompatible, durable resin optimized for medical workflows. It is validated for prolonged skin contact, making it suitable for wearables and healthcare devices.

Key properties:

- Compliance: Biocompatible for medical use

- Durability: Built for prolonged contact and repeated use

Best for:

- Dental appliances, splints, and medical wearables

- Devices requiring safe, skin-contact validation

Limitations:

- Higher cost compared to standard engineering resins

- Strength tuned for biocompatibility rather than maximum stiffness

Loctite 3D MED413 HDT60 Tough

Loctite 3D MED413 HDT60 is ISO 10993-compliant and maintains mechanical balance near body temperature. It offers a “tough” profile with enough durability for medical components like hearing aids.

Key properties:

- Standard: ISO 10993-compliant

- Heat Resistance: Stable near body temperature

- Strength Profile: Balanced toughness for medical duty

Best for:

- Hearing aids and medical parts requiring safe wear

- Healthcare components exposed to regular handling

Limitations:

- Requires specialized handling and validation protocols

- Not designed for top-tier stiffness like composite-grade resins

Formlabs ESD Resin

Formlabs ESD Resin is a specialty material designed for static-dissipative performance. While it delivers stiffness and strength similar to engineered resins, its true purpose is to protect sensitive electronics during use.

Key properties:

- Strength and Stiffness: Comparable to engineering resins

- Static Dissipation: Prevents static discharge around electronics

- Surface Finish: Smooth, functional appearance

Best for:

- Trays, fixtures, and enclosures near electronic equipment

- Functional parts needing both resin compatibility and ESD safety

Limitations:

- Impact resistance is moderate compared to tough resins

- Less suited for high-shock applications

Siraya Tech Tenacious (Flexible/Tough)

Siraya Tech Tenacious is known for its flexible-tough balance. It bends without snapping, which makes it useful as a standalone material or as an additive blended with more brittle resins.

Key properties:

- Flexibility: Can bend significantly without breaking

- Toughness: Enhances impact performance when blended

- Resin Compatibility: Mixes with brittle resins for better impact balance

Best for:

- Blending into brittle resins to increase toughness

- Thin resin prints that need controlled flex under load

Limitations:

- Lowers tensile strength and stiffness when used neat

- Not ideal for applications demanding high compression strength

PrimaCreator Value Flex Resin

PrimaCreator Value Flex Resin is a budget-friendly flexible resin with high elongation, often used for soft-touch applications. Its transparent surface finish mimics elastomeric materials.

Key properties:

- Elongation: Around 130%

- Appearance: Transparent, elastomer-like finish

- Performance: Prioritizes flexibility over rigidity

Best for:

- Soft-touch parts and grips

- Applications needing shock absorption and bendable parts

Limitations:

- Lower tensile strength and stiffness compared to engineering resins

- Dimensional accuracy under sustained load is limited

Raise3D ESD Resin

Raise3D ESD Resin combines mechanical performance with electrostatic dissipative properties. It aligns with other engineered specialty resins yet exceeds many in raw strength benchmarks.

Key properties:

- Tensile Strength: 68 MPa

- Flexural Strength: 126 MPa

- Impact Strength: 28 J/m (notched Izod)

- Heat Deflection Temperature: 76 °C

- Performance: Balanced stiffness with static-safe functionality

Best for:

- Housings, enclosures, and tooling in electronics-heavy environments

- Parts requiring both mechanical strength and ESD protection

Limitations:

- Does not reach the top compression strength of composite resins

- Impact resistance is moderate compared to tough blends

Raise3D High Detail (Apricot) Resin

Raise3D High Detail Resin is engineered for dimensional accuracy and surface finish but maintains mechanical properties that reach into the engineered tier.

Key properties:

- Tensile Strength: 58 MPa

- Flexural Strength: 98 MPa

- Impact Strength: ~34 J/m (notched Izod)

- Heat Deflection Temperature: ~67 °C

- Performance: High-resolution detailing with mechanical robustness

Best for:

- Prototypes requiring accuracy and resilience

- Thin resin parts needing both feature precision and impact absorption

Limitations:

- Falls just below the 100 MPa flexural benchmark

- Less stiff and heat-resistant than Rigid 3K or ESD Resin

Comparison of Strong Resin Properties

| Resin | Tensile Strength (MPa) | Flexural Strength (MPa) | Impact Strength (J/m) | HDT (°C) |

| Raise3D Rigid 3K Resin | 78 | 139 | 30 | 97 |

| Liqcreate Strong-X | 52–70 (up to ~84 cured) | 121–140 | 17–20 | — |

| Liqcreate Composite-X | ~85 | 150–170 | Moderate | — |

| Elegoo ABS-Like Resin | 30–52 | 40–70 | 41–48 | — |

| Formlabs Flexible 80A Resin | 3.7–8.9 | 31–39 | High tear resistance | — |

| Raise3D Standard White Resin | 67 | 108 | 33 | 77 |

| Raise3D ESD Resin | 68 | 126 | 28 | 76 |

| Raise3D High Detail Resin | 58 | 98 | 34 | 67 |

How Do Raise3D Resins Outperform Competitors

Raise3D resins consistently deliver balanced performance across tensile, flexural, and impact benchmarks while maintaining reliable SLA and DLP resin compatibility. Rigid 3K sits among the top tier for stiffness, while ESD adds functional electrostatic safety at high strength levels.

Even the Standard White resin surpasses ABS-like competitors in flexural strength, while High Detail Resin ensures accurate geometry without sacrificing toughness.

For electronics, Raise3D ESD is the clear solution. For structural jigs and fixtures, Rigid 3K leads. For prototypes with fine features, High Detail Resin provides the best combination of accuracy and mechanical performance.

What are the Applications of Strong Resin Prints?

Strong 3d printing resin opens doors well beyond decorative resin prints. By balancing tensile, flexural, and compression strength, these materials provide real solutions for duty applications where performance matters. The right choice depends on resin compatibility with your 3d printer, the load case, and the environment.

- Prototyping: Tough resins handle snap-fits, hinges, and iterative engineering models.

- End-use parts: Engineering and composite blends serve for jigs, housings, and fixtures.

- Dental/medical: Biocompatible resins allow splints, surgical guides, and wearables.

- Engineering components: Composite and rigid resins deliver stiffness and flexural resistance.

- Jewelry: Castable resins enable precise burnouts for investment casting.

- Miniatures: Standard resins produce high-detail models with fine surface finish.

- Creative/art: Flexible or clear resins bring variety for design pieces and visual objects.

- Functional tools: Strong blends provide accuracy and durability in workshop applications.

When Should You Use Strong Resin Instead of Standard Resin?

You should choose strong resins when resin prints must survive stress, handling, or repeated duty applications.

For example, functional prototypes with snap-fits, hinges, or mechanical joints benefit from tensile targets above 55 MPa and flexural strengths over 100 MPa. Engineering-grade resin prints or small fixtures also require added stiffness and resistance to deformation.

By contrast, if your focus is visual appeal or surface finish, standard materials are enough. Miniatures, display models, or artistic resin prints do not need the compression strength of engineered blends. You can save on cost and simplify processing by using these lower-duty options.

Strong 3d printing resins are ideal when function and durability outweigh looks. Standard blends remain best when detail, resolution, and speed matter more than strength.

How Does Resin Strength Compare to Traditional Materials?

When you evaluate resin prints against traditional manufacturing methods like injection molding, metals, and composites, the differences become clear. Engineered 3D printing resin can achieve tensile values of 55–90 MPa and flexural strengths over 130 MPa, which puts them in the same class as common thermoplastics. Compression strength in reinforced composites can reach around 158 MPa, showing real potential for duty applications.

Compared to commodity plastics such as PLA, ABS, or PETG, strong resin prints often match or exceed stiffness and surface finish. Impact strength, however, tends to lag unless you use “tough” formulations.

Against engineered plastics like molded ABS, PC, or nylon, injection molding still provides higher ductility and repeatable strength, making it more reliable for high-shock environments.

Metals remain well beyond resin compatibility, with yield strengths many times higher, meaning you should switch to aluminum or steel for safety-critical applications. Fiber-reinforced composites also outperform resin prints because they incorporate continuous fibers, which resins cannot replicate.

In short, strong 3d printing resins let you bridge prototyping and functional use. But when applications demand maximum impact toughness, high heat resistance, or structural safety margins, injection molding, metals, or advanced composites are the better solution.

Conclusion

The real strength of resin prints isn’t just about the resin itself, it’s about how you put the whole system together.

With the right chemistry and a proper cure, you can push tensile strength into the 55–90 MPa range, flexural values past 130 MPa, and even see composites climb to 150–170 MPa flexural with compression near 158 MPa. Those are serious numbers that prove resin prints can hold their own in real applications.

But here’s the key: strength is never just material deep. You need to match the resin family to your load case, design with fillets and smooth transitions, and validate with proper testing. And don’t forget about the environment, UV and heat can chip away at performance unless you plan coatings or protective measures.

If you take that approach, you’re not just making resin prints, you’re creating parts you can trust to perform, whether it’s in a prototype, a jig, or an end-use product.

Frequently Asked Questions

Is Resin Stronger Than PLA?

If you compare resin prints directly to PLA, the results depend on which property you care about most. Engineered 3d printing resin often delivers tensile strengths in the 55–90 MPa range, comfortably higher than PLA’s typical 28–50 MPa. Flexural performance follows the same trend, with composites reaching above 130 MPa, while PLA stays lower. This means resin prints can outperform PLA when stiffness and resistance to bending are your priority.

Where PLA still holds an advantage is impact toughness. Standard rigid resins are prone to brittle failure, while PLA absorbs shock better. However, “tough” or ABS-like resin formulations narrow this gap, providing more balance between stiffness and durability.

Is Resin as Strong as Steel?

No. Even the strongest 3d printing resins are not in the same league as metals like steel. Top-end resin materials may reach flexural values of 150–170 MPa and tensile strengths around 85–90 MPa, which is impressive compared to plastics or injection molding grades. But steels typically deliver yield strengths in the hundreds of MPa and can exceed 1000 MPa in ultimate tensile strength.

Beyond raw numbers, metals also bring superior fatigue resistance, toughness, and thermal stability, qualities resin prints cannot match. That is why you should never replace safety-critical, load-bearing components with resin prints.

Can Resin Prints Be as Strong as FDM?

The answer depends on which property of strength you prioritize. In tensile and flexural performance, engineered and composite 3d printing resins can rival or even surpass common FDM materials like ABS or PETG. Some resin prints achieve flexural strengths above 130 MPa, well within the engineered plastics range. That makes them a solid choice when stiffness and dimensional accuracy are the goal.

Where resin prints still lag is in impact and ductility. FDM parts, especially those made with ABS, PETG, or nylon filaments, typically handle shock and bending better. Tough resins with impact strengths around 41–48 J/m help close the gap, but they rarely surpass high-ductility FDM.

Do Resin Prints Break Easily?

Standard resins do tend to break more easily because they are inherently brittle and sensitive to UV degradation. If you only use them for cosmetic objects, brittleness may not matter. But for functional resin prints, you should consider tough or engineering resins instead. These families resist cracking under load and can reach tensile and flexural benchmarks closer to injection molding plastics.

Post-processing plays a major role. A thorough wash and proper UV cure greatly increase compression strength and impact resistance. Adding fillets, thicker sections, and protective coatings also extends longevity, especially for outdoor applications.