The Department of Biomechatronics Engineering of National Chung Hsing University

Challenges

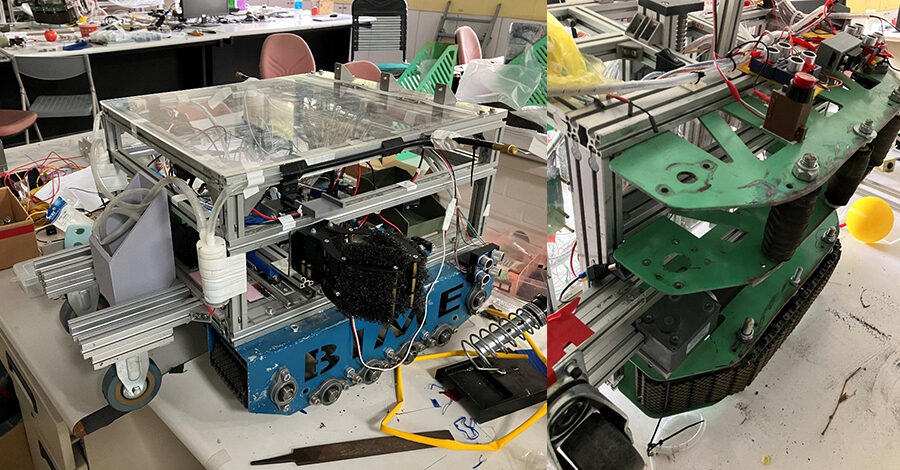

The laboratory’s main research areas include robots and micro-generators that generate electricity through friction, so there is often a need to prototype complex parts . Students’ special projects often require the use of 3D printers to make models or conduct functional tests. In addition, in the field of bio-industry mechatronics engineering, five universities will jointly hold a field robot competition every year, and the participating teams need to quickly and accurately manufacture various parts.

In the early days, the team relied on iron sheets to make prototypes manually, which was not only time-consuming and labor-intensive, but also difficult to ensure the firmness and precision of the finished product. Although a 3D printer was later introduced, the unstable performance of the equipment often led to printing failures.

Dr. Tsai and his team