3DPMolds Background

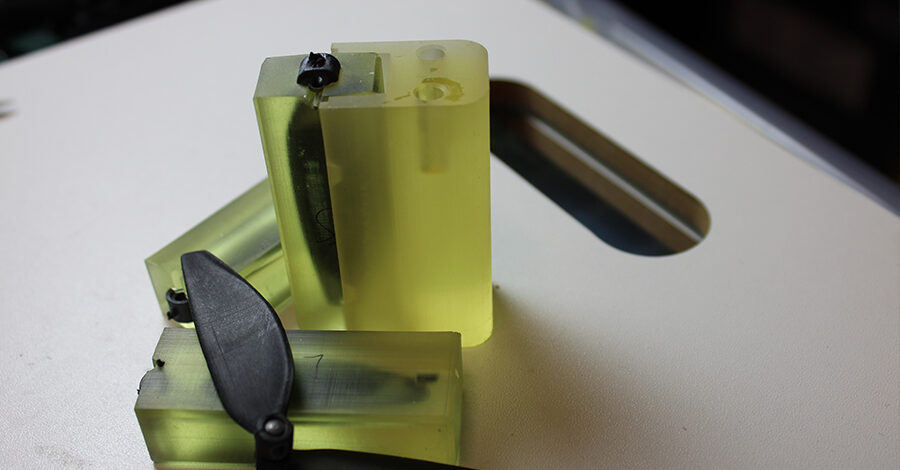

3DPMolds is a company fully dedicated to the use of 3D printed molds in the development workstream of injection molders. More than a decade of hands-on experience has provided 3DPMolds an in-depth understanding of the factors that determine successful manufacturing outcomes.

Challenge: Ensuring Precision and Repeatability

As 3DPMolds expanded its mold production capability, maintaining consistent quality and process control across multiple iterations became a challenge.

- Each new resin and design requires different exposure, curing, and heating parameters.

- Mold lifetimes are short, sometimes just one or a few shots per mold, increasing the need for print process repeatability.

- Manual handling of files and settings increases the risk of errors during process setup.

- Any printer downtime can disrupt tight project timelines.

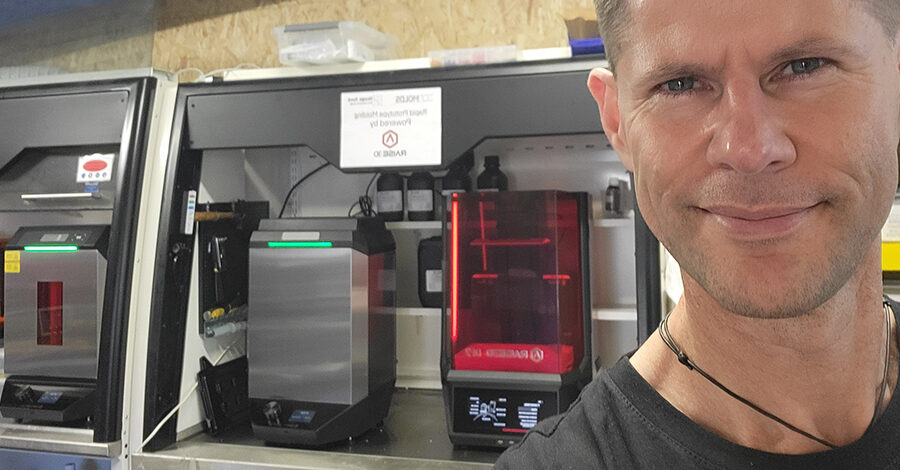

Solution: Adopting the Raise3D DF2

In early 2025, 3DPMolds adopted the Raise3D DF2 solution, a complete resin printing workflow that includes printing, cleaning, and post-curing systems. Optimized for high precision and repeatability, the DF2 features several elements particularly valuable for 3D printed mold manufacturing:

The DF2 system is optimized for industrial applications requiring precision and repeatability, providing:

- An open-material program that allows users to run certified third-party engineering resins to meet a diverse range of needs

- An integrated RFID workflow that links slicing, printing, washing, and curing data to each job

- A traceable workflow, ensuring that every process follows pre-defined parameters

3D-Printing-Empowers-High-End-Bicycle-Manufacturing-Cover.jpg)