Pro3 HS Series

FFF • Dual Extrusion • High-Speed Printing up to 300mm/s • RFID Traceable Workflow

Pro2 Series

FFF • Dual Extrusion • HEPA Filter With Activated Charcoal • Up to 300°C

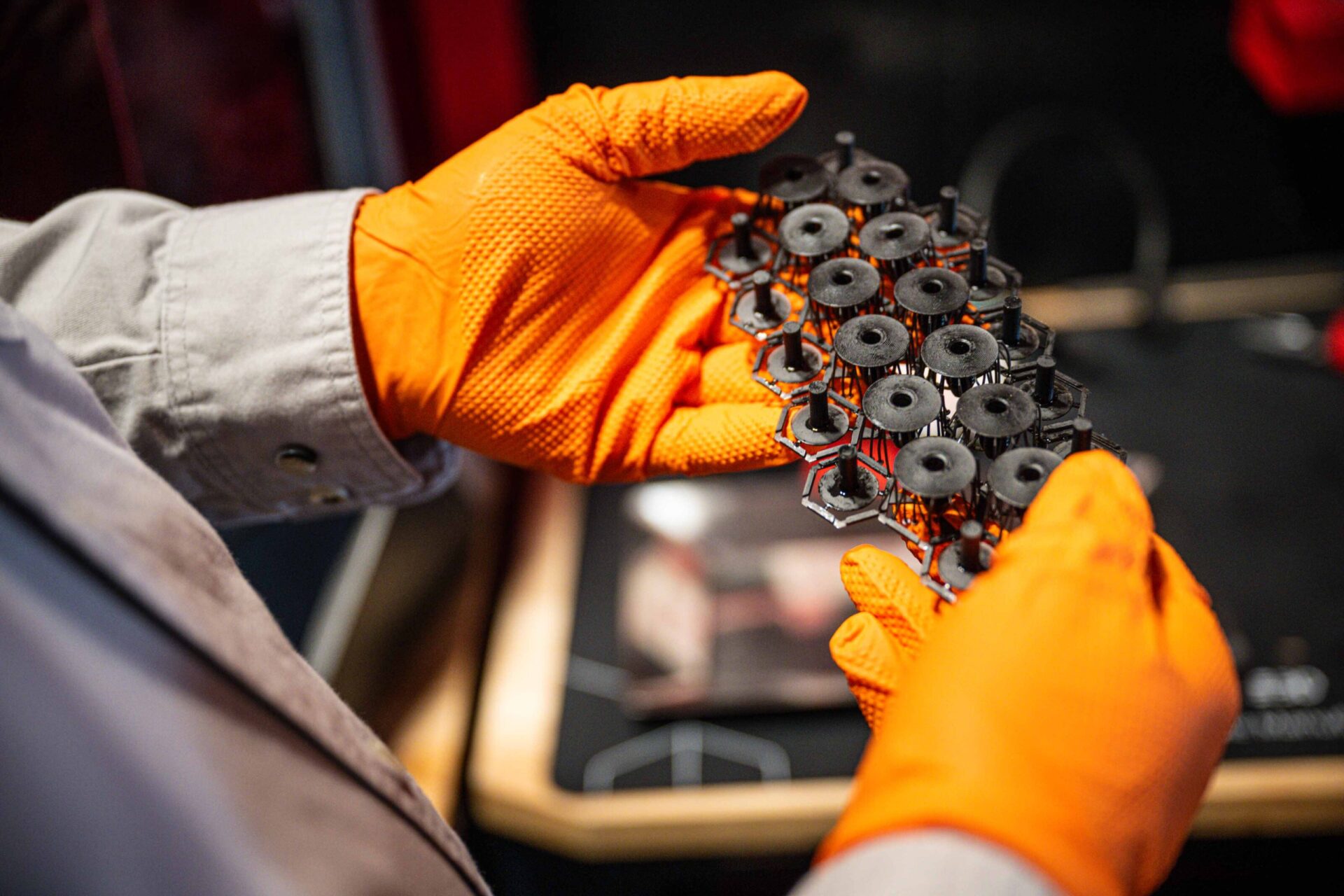

RMS220

SLS • Low TCO • High Output • High-Precision Prints • Industrial and Functional Material

DF2+ (DLP Resin)

DLP • True DLP Precision • Faster Prints • RFID Traceable Workflow • Broad Resin Portfolio

DF2 (DLP Resin)

DLP • High Resolution Resin Printing • RFID Traceable Workflow • Wide Range of Resin Compatibility

E3

FFF • Dual IDEX • Flexible and Fiber-Reinforced Filaments • Enclosed Build Chamber

E2CF

FFF • Dual IDEX • For Fiber-Reinforced Filaments • Dry Boxes • Enclosed Build Chamber

E2

FFF • Dual IDEX • For Flexible Materials up to Shore Hardness 70A • Enclosed Build Chamber

RMF500

Large-Format FFF (500 × 500 × 500 mm) • Dual IDEX • Carbon Fiber Composites & High-Strength Polymer