Reading Time: 18 Minutes

When you start working with resin 3D printing, you quickly see how much the material choice influences your results. Resin is a liquid photopolymer that cures under UV light, but the way it reacts depends on the process. SLA uses a laser to trace each layer, while DLP and MSLA/LCD project entire layers at once.

Most resin types are designed for either 385 nm or 405 nm light, and matching that wavelength with your printer’s light engine is essential if you want consistent, reliable prints.

The main resin families cover different needs:

- Standard and draft blends are great for everyday models and quick prototypes.

- Clear and transparent options serve optical or aesthetic parts.

- Tough or ABS-like resins give you stronger, functional pieces that can handle stress.

- Flexible and elastic types let you create grips, seals, or damping components.

- High-temp, rigid, and ceramic-filled resins are built for tooling, fixtures, and exposure to heat, while dental and castable formulations support medical models, crowns, and jewelry casting.

What makes resin printing so appealing is its ability to deliver very fine detail and smooth surfaces, though you should also remember that most resins are brittle compared to thermoplastics, UV-sensitive, and not food-safe. Prices can range from around $15 to more than $200 per liter, so the choice you make also comes down to budget.

In this article, we’ll focus on how to match resin type to your projects and why that decision makes all the difference.

Which Standard Resin Types are Commonly Used?

When you look at resins for 3D printing, some categories stand out as the most widely used across resin printers. These are favored because they balance cost, accessibility, and reliable performance for a broad range of 3D printing projects.

- Standard or rigid resins are often the first choice for prototypes and everyday models because they offer a smooth surface finish and predictable results.

- Clear resins provide transparency for parts where light transmission or visual detail matters.

- Water-washable resins appeal to hobbyists and professionals who want easier cleanup without solvents, though they are more sensitive to moisture.

- Flexible resins add elasticity for parts that need to bend, while draft formulas increase printing speeds for quick iterations.

- More recently, “8K” high-resolution blends have been marketed to meet the demands of miniatures and display-quality models, though actual detail is still limited by the optics and pixel density of resin 3D printers.

Each resin type comes with trade-offs, whether that is brittleness, curing sensitivity, or limited long-term stability under UV light. Understanding these limitations is essential when deciding how your parts should function.

To help you compare, let’s look closely at the most common standard resin types and what makes them useful for your 3D printing applications.

Standard / Rigid (General-Purpose)

Standard or rigid resins are the baseline material you will encounter when working with resin 3D printing. These resins are designed to provide ease of use and consistency, making them ideal for both beginners and experienced users.

They typically have a viscosity between 100 and 350 mPa·s at 25 °C, which allows liquid resin to flow well during the 3D printing process. Common color options include white, gray, and black, along with tinted variations for specific projects. You can expect a smooth surface finish, excellent dimensional accuracy, and sharp detail reproduction, though the material is brittle compared with thermoplastics such as PLA or acrylonitrile butadiene styrene (ABS).

Average prices range from about $15 to $40 per liter, making this resin type one of the most economical options in the 3D printing industry. With proper post-processing, including sanding and painting, you can achieve a professional appearance.

Key applications and properties include:

- Prototyping: Ideal for visual models and fit-checks where stiffness is preferred.

- Surface finish: Produces crisp edges and a clean look suitable for display parts.

- Compatibility: Works with SLA, digital light processing DLP, and LCD 3D printers tuned to the proper wavelength.

- Limitations: Limited impact resistance, sensitivity to UV light leading to yellowing, and reduced durability outdoors.

Clear / Transparent

Clear or transparent resins are chosen when you want light to pass through the final 3D printed part. These materials are capable of producing translucent to glass-like finishes, depending on the finishing workflow you use.

They are commonly available in clear form or with light tints such as blue or amber. However, achieving true optical clarity requires careful post-processing. Most workflows involve sanding through progressive grits, polishing, and then applying a clear coat to minimize haze and enhance transparency.

Key applications and properties include:

- Light-transmitting parts: Suitable for light pipes, lenses, or display models that need visibility through the material.

- Optical clarity: With the right polishing steps, you can approach the appearance of glass or PMMA-like plastics.

- Durability: Prone to brittleness and at risk of UV yellowing, though some PMMA-like blends resist discoloration better.

- Design considerations: Orient large optical faces flat in the build to reduce refraction lines from the LCD or DLP pixel grid.

Water-Washable

Water-washable resin for 3D printing is marketed as a convenient alternative to standard resins that require isopropyl alcohol cleaning. Instead of a solvent bath, you rinse your resin prints in water to remove uncured material.

While this makes the 3D printing process feel easier, the liquid resin remains hazardous until it is fully cured, so you still need gloves, ventilation, and careful handling. The mechanical properties are often close to standard resins, with tensile strengths reported in the 30–46 MPa range and flexural values around 45–75 MPa. These numbers can represent a 20–40% improvement over older blends, but brittleness is still a concern.

If you mix this material with other 3D printer resin types, the water-washable property is lost, so consistency matters. Keep rinse cycles under a minute, air-dry thoroughly, and then proceed with the curing process under UV light to improve durability.

Main applications and properties include:

- Ease of cleaning: Short rinse cycles in water, but parts must be dried completely before UV curing.

- Moisture sensitivity: Residual water during the curing process increases brittleness and micro-cracking.

- Environmental notes: Uncured wash water cannot be poured down drains; you need to UV-cure the residue or dispose of it as hazardous waste.

- Price band: Typically ranges from about $20 to $60 or more per liter, depending on brand and formulation.

Flexible / Elastic

Flexible or elastic resins introduce a completely different behavior compared with rigid materials. They mimic the feel of rubber, offering elongation and energy absorption that standard resins cannot achieve.

Shore hardness levels are often around A 80, but softer blends can reach 50A for more elastic properties. Some formulations stretch up to 150% elongation at break, allowing you to design parts such as gaskets, grips, or shock-absorbing components. You should print the part in its intended shape because post-forming after curing is limited.

You can also mix a small percentage of flexible resin with standard resin for 3D printing to improve toughness, though you should expect longer exposure times. Average prices range from about $40 to $100 per liter, reflecting their specialized role in the 3D printing industry.

Main applications and properties include:

- Use cases: Functional parts like seals, grips, and damping elements where impact resistance is needed.

- Design rules: Maintain adequate wall thickness, consider lattice infill patterns for balance, and use rounded geometries to reduce stress points.

- Trade-offs: Fine detail reproduction is reduced compared with rigid resins, and you will see longer curing times.

- Processing tips: Flexible blends benefit from longer light-off delays and slower lift speeds to improve interlayer bonding.

Draft / High-Speed

Draft resin is a type of resin for 3D printing designed for maximum throughput rather than fine detail. Its lower viscosity and fast-curing formulation allow resin printers to achieve layer exposures of about 1.5 to 2.8 seconds per layer on tuned systems.

This makes it especially valuable when you need quick prototypes, early design iterations, or large parts where speed matters more than aesthetics. You will often see thicker layer heights compared with standard resins, which reduces overall print time but also lowers resolution and smooth surface quality.

For design-intent validation, draft resin is an excellent choice, but once your prototype is finalized, you should reprint in a tougher or standard resin type for durability.

Main applications and properties include:

- Rapid prototyping: Ideal for checking part fit and geometry early in the 3D printing process.

- Speed advantage: Some workflows claim multiple times faster output compared with standard resin 3D printers, and up to ten times faster than large FDM builds.

- Trade-offs: Detail accuracy and long-term dimensional stability are weaker, and parts may deform over time.

Plant-Based / Eco

Plant-based resin is formulated with renewable feedstocks and reduced fossil-carbon content, making it appealing to those looking for a more eco-conscious choice in the 3D printing industry.

These blends often have lower epoxy levels, which leads to reduced odor during the 3D printing process and potentially fewer volatile organic compounds in your workspace. While this makes them friendlier for classrooms, hobby environments, or consumer goods prototypes, they remain hazardous until fully cured. Like any liquid resin, uncured waste should never be poured down drains. Instead, UV-cure residues, filters, and wash solutions before disposal in line with local regulations.

Plant-based resins suit visual models, education projects, and hobbyist 3D printing applications where appearance and odor control outweigh extreme performance. If you need a resistant resin for functional parts or high heat resistance, you should still turn to specialized 3D printer resin types.

Main applications and properties include:

- Lower odor: Useful in enclosed spaces where ventilation may be limited.

- Eco appeal: Reduced reliance on petrochemicals and a smaller environmental footprint.

- Limitations: Mechanical properties, surface finishes, and toughness often fall short of engineered resins.

- Price band: Mid-range, often between $30 and $70 per liter depending on brand.

“8K” / High-Resolution Pigments

“8K” resin for 3D printing is marketed to highlight compatibility with high-resolution LCD 3D printers, where the liquid crystal display defines pixel size and cross section detail. In practice, “8K” refers to the pixel width class of the LCD screen rather than a direct property of the resin itself. What makes these resins different is the use of low-scatter pigments and tuned rheology, which improve edge acuity and reduce light bleed between pixels during the curing process. This helps your resin prints achieve sharper results on machines with very high pixel density.

Main applications and properties include:

- Miniatures and dental models: Excellent when accuracy at small scales is essential, such as hobbyist miniatures or medical study models.

- Material flow: Often formulated with lower viscosity for fast peel and reduced stress on the FEP film, which can extend vat life.

- Performance gains: Some blends claim reduced brittleness and improved abrasion resistance compared with standard resin types.

- Trade-offs: Limited color options, occasional slower printing speeds to preserve surface finish, and real detail limits still tied to optics and pixel pitch.

Which Engineering and Industrial Resin Families Exist?

When you move from hobbyist resin 3D printers into industrial 3D printing applications, you encounter a set of engineering-grade resin families. These materials are built for performance, with data sheets that specify tensile strength, flexural strength, elongation at break, Shore hardness, and heat deflection temperature.

Unlike general-purpose liquid resin, these blends are validated through ASTM or ISO testing, giving you reliable numbers to compare against traditional polymers such as acrylonitrile butadiene styrene (ABS) or nylon.

Tough or ABS-like resins offer impact resistance and ductility, making them suitable for snap-fits or housings. High-temperature resins withstand heat ranges of about 180 to 260 °C HDT, enabling use in tooling or under-the-hood prototypes.

Rigid or ceramic-filled resins deliver high stiffness and dimensional accuracy but fail in a brittle manner, which makes them best for metrology fixtures. PMMA-like blends provide long-term optical stability for clear parts, while nylon-like versions improve layer bonding and flexibility for living hinges.

Other polymer-mimics, such as PC-like or PP-like, extend 3D printing technology into specialized areas where chemical resistance or toughness is required.

You should always validate performance through test coupons before committing to large 3D printing projects. So, let’s start with tough, ABS-like resins that handle impact better than the basics, and move on to other more specialized blends.

Tough (ABS-Like)

Tough resin, often described as ABS-like, is designed to replicate the balance of impact resistance and strength you expect from acrylonitrile butadiene styrene in the 3D printing industry.

Compared with standard resins for 3D printing, these blends provide higher elongation and better resilience against cracking. Shore hardness typically ranges from 68 to 75D, with tensile and flexural strengths that approach or exceed entry-level thermoplastics.

Main applications and properties include:

- Functional prototypes: Snap-fits, housings, and clips that require more toughness than standard resin prints.

- Mechanical behavior: Higher impact resistance and elongation make these parts more durable under stress.

- Processing needs: Post-curing is essential to reach the published properties; some blends also benefit from a thermal soak to increase heat resistance.

- Machining options: You can drill and tap into these materials if you use chamfered entries and avoid sharp corners that may cause crack initiation.

Heat-Resistant / High-Temperature

Heat-resistant resins push resin 3D printing into demanding thermal environments. They are formulated to deliver heat deflection temperatures in the range of about 180 to 260 °C, with some reporting service use up to 230 °C.

That level of performance makes them suitable for hot-fluid tooling, under-the-hood components, or fixtures exposed to elevated temperatures. These blends typically have low thermal expansion, which preserves dimensional accuracy during thermal cycling.

Main applications and properties include:

- Tooling and fixtures: Jigs that must withstand heat exposure without warping or losing precision.

- Thermal stability: High HDT values allow parts to hold shape under continuous load at high temperatures.

- Processing cautions: Post-curing and annealing are often required to achieve datasheet specifications. Over-exposure can create internal stresses, so you should follow recommended curing schedules.

- Limitations: Higher cost, slower curing, and limited color options compared with standard resins.

Rigid / Ceramic-Filled

Rigid or ceramic-filled resin for 3D printing is engineered to deliver very high stiffness and dimensional stability. These materials incorporate ceramic or mineral fillers within the liquid resin, giving them mechanical properties that approach composites. Shore hardness typically sits in the high 70s D range or above, with modulus values far higher than standard or ABS-like resins. That makes them ideal for applications where precision and resistance to deformation matter more than flexibility.

Main applications and properties include:

- Metrology fixtures and jigs: Low shrinkage ensures accuracy for inspection and alignment.

- High stiffness housings: Suitable for structural parts where load-bearing capacity is important.

- Thermal and chemical resistance: These resins can withstand demanding environments without significant warping.

- Limitations: Brittle failure modes, so you should avoid thin snap features or sharp corners in your design.

- Maintenance notes: Slurry-like fillers can settle, so stir the vat regularly; the abrasive nature of the formulation also accelerates FEP and vat wear.

PMMA-Like

PMMA-like resin is designed to mimic the optical clarity and durability of polymethyl methacrylate, often called acrylic. Compared with standard clear resins for 3D printing, PMMA-like materials maintain transparency longer and resist yellowing under UV light. They also combine clarity with higher toughness, which makes them more suitable for applications that require both aesthetics and strength.

Main applications and properties include:

- Signage and light guides: Long-term transparency and durability support consumer goods and display pieces.

- Surface finish: With careful sanding, polishing, and optional flame or vapor polishing, you can achieve a smooth surface that resembles cast acrylic.

- Stability: These blends perform better under prolonged light exposure than many clear resins.

- Limitations: More expensive than general clear resin and require more post-processing steps to reach their best optical quality.

Nylon-Like

Nylon-like resin offers a balance of toughness and flexibility that makes it useful for functional 3D printing applications. It is designed to approximate the performance of polyamide used in selective laser sintering (SLS) or fused deposition modeling (FDM), though the match is not exact. What you gain is improved layer bonding, higher tensile load handling, and better fatigue resistance than with standard resin prints.

Main applications and properties include:

- Snap-fits and living hinges: Flexibility and toughness make these blends ideal for clips and hinged parts.

- Mechanical behavior: Tensile strength and elongation are significantly better than rigid resins, supporting functional prototypes.

- Moisture effects: Just like real nylon, humidity can affect mechanical properties, so drying parts before testing or assembly is recommended.

- Limitations: Some blends show color shifts or property changes over time, and they are still less durable than true SLS nylon.

Other Polymer-Mimicking Resins

Other polymer-mimicking resins aim to replicate the mechanical behavior of common thermoplastics that are otherwise produced through FDM or SLS. While these materials do not fully match the performance of true polymers, they provide a useful alternative when you need specific properties in resin 3D printing. These blends expand your options beyond ABS-like resin by targeting the attributes of polycarbonate (PC), polypropylene (PP), or similar plastics.

Main applications and properties include:

- PC-like: Designed for higher heat resistance and impact resistance, often used in functional prototypes where durability is required.

- PP-like: Tuned for ductility and chemical resistance, making them valuable for snap-fit designs, solvent-contact components, or flexible housings.

- Performance validation: These resins for 3D printing should always be tested with small calibration coupons, since they approximate rather than duplicate the properties of their thermoplastic counterparts.

- Limitations: Mechanical properties may fall short of traditional polymers, and stability can vary depending on printer type and curing process.

Which Application-Specific Resins are Available?

Castable resins are engineered for investment casting workflows, where “zero ash” burnout is essential to preserve smooth surface finishes and fine features.

Dental and medical resins add biocompatibility and sterilization resistance, but you must follow validated print, cure, and storage protocols to maintain compliance.

Large-format, often called “Mammoth” systems, emphasize handling massive build volumes with stable peel forces and long cure paths.

For these resins, you need to plan carefully for support removal and part handling because the scale introduces challenges not seen in desktop printers.

Each of these resin types demands you verify specifications on datasheets or certification documents. Burnout schedules, biocompatibility class, and vat capacity all matter.

You cannot treat them as drop-in alternatives to standard types of resin; instead, you should match them to specific 3D printing applications where certification or process control is non-negotiable.

Castable / Burnout (Investment Casting)

Castable resin for 3D printing is designed for lost-wax or investment casting workflows where residue-free burnout is critical. The defining requirement is “zero ash” performance, so the resin must vaporize cleanly during the burnout cycle without contaminating the mold. Typical burnout schedules involve gradual temperature ramps up to casting range, which protects delicate features from cracking the investment shell.

Main applications and properties include:

- Jewelry and dental casting: Produces smooth surfaces and fine detail in crowns, bridges, and small decorative pieces.

- Formulation options: Wax-like versions burn more smoothly and are easier to invest, while resin-like types provide sharper edges and detail fidelity.

- Processing tips: Always design sprues and vents to allow gases to escape, reducing porosity or incomplete burnout risk.

- Validation: Test small casting trees before committing to large batch production, as burnout performance varies with printer type and curing process.

Dental (Models, Surgical Guides, Biocompatible Classes)

Dental resins represent one of the most specialized categories of resin for 3D printing, created to deliver accuracy, safety, and regulatory compliance. These materials are split by use case: model resins support precise study models, surgical guide resins are validated for intraoral use, splint resins withstand bite forces, and temporary crown resins provide short-term restorations. Each class requires you to follow strict workflows for printing, curing, and storage.

Main applications and properties include:

- Model resins: High accuracy for study casts and aligner workflows; optimized for smooth surface finishes.

- Surgical guide and splint resins: Certified for biocompatibility, often Class I or IIa, with compatibility for sterilization by autoclave or chemical processes.

- Temporary crown resins: Tuned for intraoral durability and shade matching; validated through ISO dental standards.

- Storage hygiene: Always store sealed, in light-safe containers, and handle with clean gloves to maintain compliance.

Mammoth Resin (Large-Format SLA Ecosystem)

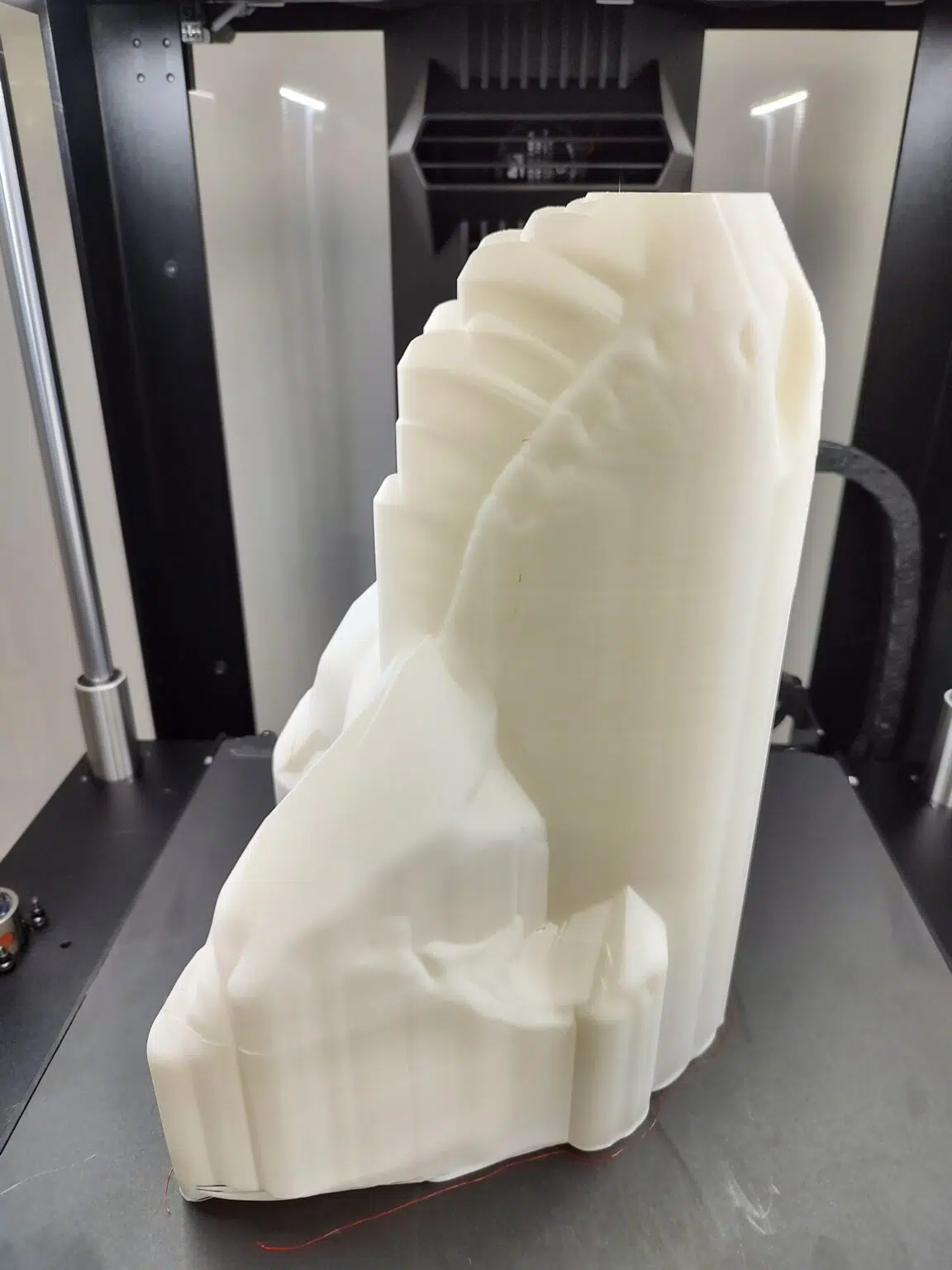

Mammoth resin is the name given to large-format SLA resin ecosystems capable of producing parts that exceed the build volumes of typical resin 3D printers. These systems operate with vats that can reach dimensions of roughly 2100 × 700 × 800 mm, enabling you to print single-piece parts that would otherwise require assembly. The liquid resin must remain stable over long cure paths, and peel forces become a major consideration.

Main applications and properties include:

- Ultra-large prototypes: Automotive panels, aerospace fixtures, and architectural models that benefit from smooth surfaces.

- Handling challenges: Parts require careful lifting, fixturing, and segmented post-curing due to their size and weight.

- Mechanical behavior: Surface quality is high, but overall mechanical strength is moderate, so designs should avoid unsupported thin walls.

- Process requirements: Expect long post-cures and heavy support structures to ensure accuracy across the entire build volume.

Raise3D Resin Types

Raise3D has developed a diverse portfolio of resins for 3D printing that support everything from quick concept models to demanding industrial and medical workflows.

These resins are optimized for MSLA, LCD 3D printers, and digital light processing DLP systems, with most tuned to 405 nm UV light while select engineering and dental blends also function at 385 nm.

When you account for their range, you see that Raise3D covers both in-house materials and validated partner collaborations with BASF Ultracur3D, Henkel LOCTITE, and Liqcreate.

In practice, this portfolio lets you choose resins for 3D printing that balance speed, strength, clarity, and compliance. Standard White, Black, Draft Grey, and High Detail support everyday prototyping, while High Clear enables PMMA-like transparency.

Tough 2K and Rigid 3K provide mechanical properties suited for housings, jigs, and metrology applications. Flexible elastomers from BASF (EL 60 and EL 4000) deliver Shore A 75–90 softness for grips or damping, while high-temperature and flame-retardant blends (LOCTITE IND147, IND249, Ultracur3D RG 9400 B FR) extend performance to tooling and electronics. Specialty solutions include ESD-safe resins for trays, biocompatible dental grades from Liqcreate, and castable wax formulations for jewelry.

Here are mapped families with Raise3D examples:

- Standard / Rigid: Standard White/Black, High Detail, Rigid 3K

- Clear / Transparent: High Clear

- Flexible / Elastic: Ultracur3D EL 60, EL 4000

- Draft / High-Speed: Draft Grey

- “8K” / High-Resolution Pigments: High Detail (Apricot)

- Tough (ABS-like): Tough 2K, LOCTITE 3843, IND405

- Heat-Resistant / High-Temperature: LOCTITE IND147, IND249; Ultracur3D RG 9400 B FR

- Rigid / Ceramic-Filled: Ultracur3D RG 3280, Rigid 3K

- PMMA-like: High Clear

- Other Polymer-Mimics: Raise3D ESD, Ultracur3D RG 9400 B FR

- Castable / Burnout: Liqcreate Wax Castable

- Dental / Medical: Liqcreate Dental Model Pro Grey/Beige, Premium Model, Bio-Med Clear

Raise3D Resin Portfolio

| Resin Family | Resin Type | Key Properties | Applications |

| Standard / Rigid | Standard White/Black | General-purpose, smooth surface, economical | Prototypes, visual models |

| Standard / Rigid | High Detail | High detail accuracy, crisp edges | Miniatures, precision parts |

| Standard / Rigid | Rigid 3K | High stiffness, dimensional stability | Fixtures, housings |

| Clear / Transparent | High Clear | Transparent, PMMA-like clarity | Optical parts, display windows |

| Flexible / Elastic | Ultracur3D EL 60 | Shore A ~75, flexible and elastic | Grips, dampers |

| Flexible / Elastic | Ultracur3D EL 4000 | Shore A ~90, durable elastomer | Flexible fixtures, damping |

| Draft / High-Speed | Draft Grey | Fast print speeds, lower detail | Concept models, fast iterations |

| “8K” / High-Resolution | High Detail (Apricot) | High-resolution pigments for fine detail | Miniatures, dental models |

| Tough (ABS-like) | Tough 2K | ABS-like impact resistance, snap-fits | Housings, consumer goods |

| Tough (ABS-like) | LOCTITE 3843 | Tough engineering-grade, functional prototypes | Functional prototypes, housings |

| Tough (ABS-like) | LOCTITE IND405 | Durable, high elongation | Snap-fits, load-bearing parts |

| Heat-Resistant / High-Temp | LOCTITE IND147 | High HDT ~230°C, heat resistant | Tooling, automotive |

| Heat-Resistant / High-Temp | LOCTITE IND249 | High stiffness, high-temp resistance | Industrial jigs, aerospace |

| Heat-Resistant / High-Temp | Ultracur3D RG 9400 B FR | Flame retardant, electrical applications | Electrical fixtures |

| Rigid / Ceramic-Filled | Ultracur3D RG 3280 | Ceramic-filled, metrology fixtures | Precision jigs, metrology |

| Rigid / Ceramic-Filled | Rigid 3K | High rigidity, engineering jigs | Durable prototypes |

| PMMA-like | High Clear | Clear optical applications | Optical clarity parts |

| Other Polymer-Mimics | Raise3D ESD | Electrostatic discharge safe, electronics trays | Electronics trays, housings |

| Other Polymer-Mimics | Ultracur3D RG 9400 B FR | FR, tooling, electrical resistance | Automotive, aerospace fixtures |

| Castable / Burnout | Liqcreate Wax Castable | Zero ash burnout, investment casting | Jewelry casting, dental casting |

| Dental / Medical | Liqcreate Dental Model Pro (Grey/Beige) | Dental modeling, high accuracy | Dental labs, aligners |

| Dental / Medical | Liqcreate Premium Model | Study models, biocompatible | Study models, orthodontics |

| Dental / Medical | Liqcreate Bio-Med Clear | Biocompatible, medical devices | Medical R&D, surgical tools |

How Do You Choose the Right Resin for Your Part and Project?

To choose the right resin for 3D printing you need to align your application with performance requirements, check your printer’s light engine compatibility, and balance surface quality with budget. A quick playbook helps you avoid costly mistakes.

- Application: Define what the part must do, prototype, snap-fit, optical piece, or dental guide.

- Properties: Match mechanical targets like tensile strength, elongation, and impact resistance, plus thermal needs such as HDT and Tg.

- Printer Compatibility: Confirm resin type with your SLA, DLP, or LCD 3D printer’s wavelength (commonly 385 or 405 nm).

- Finish: Decide if you need smooth surface finishes, transparency, or high-resolution detail.

- Cost: Set your budget, draft and standard resins run ~$15–$60/L, flexible resins $40–$100/L, and engineering blends can exceed $100/L.

Mechanical Properties

When you evaluate resins for 3D printers, mechanical properties define whether your part survives its intended use. Tensile strength measures resistance to pulling, flexural strength captures stiffness under bending, elongation at break shows ductility, and impact resistance indicates toughness. Each metric should account for both the material and the geometry you design.

Design choices matter as much as resin type. Fillets at stress points reduce crack formation, while thicker walls and structural ribs add stiffness. If you need functional prototypes or snap-fits, tough resins with Shore D ratings of around 68–75 are better suited than brittle standard blends.

Flexible blends may reach elongation levels of ~150%, ideal for dampers and grips but not for fine details. Ceramic-filled resins deliver stiffness close to metrology needs but will fail brittlely if stressed.

Yes, geometry and toughness matter, but heat can undo a design just as quickly. That’s why thermal properties come next.

Thermal Properties

Thermal performance determines if your 3D printed parts can survive warm or demanding environments. Heat deflection temperature (HDT) shows how a resin withstands load at elevated temperatures, while glass transition temperature (Tg) signals when the polymer starts to soften. For many engineering resins, HDT values can range between 180–260 °C, with some high-temp grades reporting sustained use near 230 °C.

Annealing is often required to unlock these datasheet values. After the UV curing process, controlled thermal treatment improves heat resistance and dimensional stability. Parts designed for tooling, under-hood prototypes, or fixtures in aerospace benefit from low thermal expansion, which ensures accuracy over time.

Thermal stability keeps your parts from warping, but many projects also demand visual clarity and UV stability, so we’ll discuss the optical properties that matter.

Optical Properties

Optical behavior is often the deciding factor when you want your 3D printed part to be more than functional. Clear resins can achieve transparency, but only with careful finishing workflows that involve sanding through progressively finer grits, polishing, and in some cases applying a clear coat. PMMA-like resin formulations are particularly valuable here because they resist yellowing under UV light better than many standard clear options.

Color options also play a direct role in resolution. Dark pigments can mask pixel lines on liquid crystal display printers, while light or translucent shades reveal more of the printer’s pixel pattern. Orientation matters as well: laying optical faces flat reduces refraction and minimizes visible layer boundaries. For display pieces or consumer goods that require long-term clarity, UV-protective coatings or covers extend durability. Optics are important, but surface finish sells the part.

Surface Finish & Resolution

Surface quality and resolution in resin 3D printing are a combination of machine optics and resin chemistry. Layer visibility can be reduced by choosing a low-viscosity liquid resin that flows evenly and minimizes peel artifacts. Pigment particle size and dispersion directly affect edge sharpness, finer pigments improve micro-detail, while poorly dispersed blends can blur features.

For “show surfaces,” post-processing is unavoidable. A sanding ladder, beginning with coarse grit and stepping down to very fine papers, followed by polishing compounds, delivers the smooth surface you need for presentation models or miniatures. Some “8K” high-resolution formulations are tuned for modern high-PPI LCD 3D printers, but remember that pixel pitch and optics ultimately limit detail.

Getting the surface finish and resolution right without considering the printing speed is a waste of time.

Printing Speed & Curing Behavior

Printing speed is often the first feature that draws you to draft resin, but you should understand the trade-offs. Fast-curing blends may allow exposure times as low as 1.5–2.8 seconds per layer, especially on tuned LCD or digital light processing DLP printers. Lower viscosity helps layers settle quickly, but it also increases peel forces on the vat film. Using the right peel strategy, such as slower lift speeds or adjusted angles, reduces stress on both the resin tank and the part.

With rapid resins, detail fidelity and long-term stability can decrease compared to standard blends. Before moving into full-scale production, you should validate print quality with calibration models and stress tests. Some light engines, particularly at lower wavelengths, demand higher UV light power to achieve proper curing energy.

Now that we’ve highlighted how important the print speed is, the real test is weeks in the wild, UV, moisture, solvents

Durability & Environmental Resistance

Resin 3D printing offers smooth surfaces and high accuracy, but durability in real environments is not the same for every resin type. UV light, moisture, and solvents are the main forces that determine long-term performance. For instance, water-washable resins are more moisture-sensitive; you need to dry them thoroughly before curing and avoid placing them in humid service conditions. Some standard resins have shown multi-year sunlight exposure with limited degradation, but unless the datasheet explicitly validates outdoor use, you should assume that UV protection is required.

You can extend the service life of parts by using protective coatings, UV-resistant clear coats, or physical covers. When printing for outdoor signage, tooling near chemicals, or even decorative objects, include environmental screening in your planning.

Another real decision comes down to use cases. Prototypes, medical devices, or tooling all demand different resin classes.

Application & End-Use Context

Selecting a resin type is dependent on the context of your 3D printing project. Cosmetic display models can rely on standard or clear resins where surface quality matters most. Functional prototypes or tooling aids demand toughness, higher heat deflection temperature, or chemical resistance. If your part is intended for dental or medical service, you must use validated biocompatible classes and follow storage and sterilization protocols.

For investment casting, only castable blends that achieve ash-free burnout schedules preserve surface finishes. Tooling applications near heat require high-temperature resins with low thermal expansion to maintain precision. By defining whether your goal is flexibility, cosmetic appeal, or regulatory compliance, you set the right filters before narrowing down resin for 3D printing choices. Keep in mind that after the end-use tells you the resin to pick, post-processing steps can still make or break your results.

Post-Processing Needs

Every resin print requires proper post-processing to achieve stability and durability. The workflow follows a sequence: rinse, dry, then UV cure. If you use water-washable resins, keep rinse times short and allow complete drying before curing; residual water can lead to brittleness. With standard resins, isopropyl alcohol or alternative solvents are more common.

Support handling also shapes final results. For castable resin printing, remove most supports before curing to avoid scarring the investment surface. Sanding, painting, or polishing steps can take resin prints from prototypes to presentation-ready parts. Each resin type has unique post-curing requirements, engineering blends may need thermal soak cycles, while cosmetic models might only need light curing for surface finishes. Support removal and curing shape your finish, but every project also has a budget. That’s why cost and availability are very important.

Cost & Availability

Standard and draft resin blends typically fall in the $15–$60 per liter range, making them the most accessible for hobbyists or batch production of cosmetic models. Flexible resins are usually priced higher, between $40 and $100 per liter, while heat resistant and engineering-grade resins can range from $70 to more than $200 per liter. You should always account for more than the resin price itself.

Hidden costs accumulate quickly in the 3D printing process. Consumables such as isopropyl alcohol for rinsing, water or solvent disposal, nitrile gloves, filters, and replacement FEP films for resin printers all impact the budget. Filled resins, including ceramic or glass-loaded types, can wear FEP films faster, adding to maintenance expenses.

Which Resin Types are Best for Miniatures and for Large Models?

For miniatures, resolution is everything. High-detail and “8K” resin formulations excel because they align with the pixel density of liquid crystal display printers. Low-viscosity blends help capture fine surface finishes while also reducing peel artifacts that could blur details. Rigid or standard resins are popular for paintability, while clear or PMMA-like types add visual effects for jewelry or fantasy miniatures. If you are working in this scale, orienting faces carefully and choosing pigments that don’t scatter light too aggressively ensures crisp results.

Large models bring a different challenge. Draft resin speeds up iteration, but for final builds you should consider tough or rigid types for better structural stability. In some SLA 3D printing ecosystems, “Mammoth” vats allow single-piece parts up to around 2100 × 700 × 800 mm. At this size, support density, segmenting strategies, drain holes, and handling plans matter as much as material choice.

What Kinds of 3D Printers Use Resin, and How Does Compatibility Work?

Resin 3D printing spans three main technologies: SLA, digital light processing DLP, and MSLA or LCD systems. SLA 3D printers use a laser that point-scans across the vat, curing liquid resin line by line.

DLP and MSLA instead project or mask a full layer at once, which increases printing speeds and improves consistency across the build platform. While all three deliver smooth surfaces, SLA often produces slightly higher accuracy on small cross sections, whereas LCD 3D printers balance resolution and cost efficiency.

Most resins are tuned to cure at 405 nm, though industrial blends may target 385 nm. Lower wavelengths typically demand higher light engine power to achieve the same cure energy because resin absorbs less efficiently. Some versatile formulations cure across a broader 225–415 nm band, but for reliability you should match your resin for 3D printing with your machine’s light source.

Industrial resin printers can exceed one cubic meter of build volume, making peel management and post-cure times more complex. Lower viscosity resins reduce peel forces and extend FEP life, while filled or resistant resin types require more frequent vat checks.

How Should You Set Up and Tune Resin Profiles and Parameters?

Resin printing performance depends on well-tuned profiles. These profiles live partly in the slicer and partly on the printer, defining how light, lift, and curing interact with liquid resin. A safe starting point is the datasheet from the manufacturer, but you should always run calibration coupons to validate exposure windows, layer height, and mechanical properties.

Fast resins can use shorter exposure times and higher lift speeds, while flexible materials need slower lifts and longer cures to maintain layer adhesion.

Water-washable resin for 3D printers benefits from longer dry times before UV curing to prevent embrittlement. Keeping a change log as you iterate helps you refine parameters without losing track of what worked best, and to tune effectively, you first need to know what a resin profile actually is.

What is a Resin Profile?

A resin profile is the set of parameters that tells your printer how to interact with the liquid resin during the 3D printing process. It includes exposure time per layer, number of bottom layers, lift distances, lift speeds, and light-off delay. These variables control not just whether resin prints stick to the build platform but also how smooth the surface finishes appear and whether parts achieve their intended strength.

In most workflows, profiles are stored within the slicer software, though some 3D printers allow on-board adjustments. For example, if you switch from an abs-like resin to a heat resistant blend, exposure windows and curing times will change. Draft resin types may use thicker layers and faster lifts, while high-detail models demand more conservative settings. Once you understand the idea of a profile, the next step is breaking down its key parameters.

What are Key Parameters in Resin Profiles?

Every resin printing workflow relies on carefully defined parameters that govern how liquid resin cures into a 3D printed object. Exposure time sets how long each layer is illuminated by UV light. Bottom exposure controls the adhesion of the first few layers to the build platform, preventing early print failures. Layer height determines the smoothness of the surface finish and directly influences printing speeds. Lift speed and retraction speed manage peel forces; too fast, and resin prints may delaminate. Rest times allow the liquid resin to flow back under the part before the next exposure, critical for consistent accuracy. Temperature also matters, since resin viscosity shifts with ambient conditions, affecting stability and detail. Another thing that matters is fine-tuning the parameters through calibration, because that’s how you reach the best results.

Fine-Tuning Your Resin Profile

Once the basic parameters are in place, fine-tuning is what brings consistency and precision. Calibration prints are the best starting point. These test pieces let you read failures: under-exposure shows as weak adhesion or “elephant skin” textures, while over-exposure causes brittleness and blurred edges. Adjust exposure times in small increments, typically 0.2–0.3 seconds, to avoid overshooting.

Fast resin types often succeed at around 1.5–2.8 seconds per layer, while standard blends land closer to 2–3.8 seconds. Lift speeds should be reduced if you see delamination or layer shifts, especially on flexible resins. Keep a change log, noting the resin type, printer, and conditions for each adjustment. This record ensures you do not lose track when switching between 3D printing projects or resin printers.

How Should You Handle, Store, and Dispose of Resin Safely?

Resin for 3D printing is a powerful material, but it must be handled with care from the moment you open the bottle until the last drop is cured.

Let’s go over a few tips that can help;

- Proper Storage & Shelf Life

Resin for 3D printing is sensitive to light, temperature, and contamination. You should store bottles in opaque containers, sealed tightly, and kept in a cool, dark space around 20 °C (68 °F). Most unopened bottles of liquid resin have a shelf life of about one year, though heat or UV light can shorten this. Always shake or stir resins for 3D printing for one to two minutes before use to evenly disperse pigments and fillers. If you return unused material from the vat to the bottle, strain it first to remove cured fragments that can affect surface finishes. Expired or degraded resin may thicken, settle permanently, or produce inconsistent resin prints.

- Safety Precautions

Uncured resin is toxic and should always be handled with care. Wear gloves, goggles, and long sleeves to prevent skin contact. Work in a well-ventilated area or use local extraction, especially with SLA 3D printers and LCD 3D printers that produce fumes during resin printing. If resin touches your skin, wash thoroughly with soap and water. If it gets into your eyes, flush with clean water for 20 minutes and seek medical advice. Never ingest resin, if swallowed, do not induce vomiting and get professional help. Keep spill kits nearby, cure any waste before disposal, and never leave liquid resin on work surfaces.

- Disposal & Environmental Impact

Even eco-labeled or low-odor blends remain hazardous until fully cured. You should always cure leftover liquid resin, resin-contaminated gloves, paper towels, or FEP films under UV light or in sunlight until solid. Never pour uncured resin or wash water into sinks or drains, since it contaminates water systems. Collect isopropyl alcohol or water from wash stations and cure it before disposal in line with local regulations. Although marketing sometimes emphasizes “green” claims, resin 3D printing still relies on chemicals that must be handled responsibly. With proper curing and compliance, you can reduce risks to both your health and the environment.

Checklist for safe handling:

- Storage: Keep sealed, opaque bottles at ~20 °C in a dark place.

- Shelf life: Expect ~1 year unopened; discard if viscosity or odor changes.

- Preparation: Shake/stir 1–2 minutes; strain reused vat resin.

- PPE: Gloves, goggles, sleeves, and ventilation at all times.

- First aid: Flush eyes with water 20 minutes; wash skin; seek medical care if ingested.

- Disposal: UV-cure all waste; never pour uncured liquid down drains.

How Do You Evaluate Resin Brands and Specifications Without the Marketing Noise?

Choosing between resin printers and materials can be overwhelming when every brand promises the smoothest surface or strongest performance. The best way to cut through the noise is to focus on data. Start with the TDS (technical datasheet) and MSDS (safety sheet). Look for clearly measured properties like tensile strength, flexural modulus, elongation, impact resistance, Shore hardness, and heat deflection temperature. Resins for 3D printing should also disclose viscosity at 25 °C, recommended wavelengths (usually 385 nm or 405 nm), and curing conditions.

Compare these numbers against known ranges. For example, tough resins may reach flexural strengths up to ~135 MPa, while high-temp grades cite HDTs between 180–260 °C. These values should be verified with simple coupons you can print and test yourself before scaling up. Pay attention to secondary factors like odor, moisture uptake in water-washable resins, and long-term UV stability for outdoor exposure.

You should also account for consistency. Some manufacturers offer strong warranty support and batch tracking, while others rely on open-material ecosystems that give you flexibility but less direct assurance.

Conclusion

When it comes down to it, choosing the right resin isn’t just about picking what looks good on paper, it’s about making sure it actually works for your printer, your workflow, and the environment your parts will live in. You and I both know that even the best resin will fail if it’s not matched to the right curing wavelength or if the post-cure process isn’t dialed in. That’s especially true when you’re working with heat resistant, flexible, or castable blends where precision matters most.

Keep your bottles sealed and stored cool and dark at around 20 °C, use proper PPE and ventilation every time you print, and never skip curing your waste before disposal. The easiest way to save yourself headaches is by testing new blends with small coupons first, especially if you’re experimenting with high-temp, flexible, or castable resins.

In the end, whether you’re building miniatures, prototypes, or full-scale fixtures, success comes from treating resin as both a performance material and something that demands careful handling.