CATL Headquarter (source: https://nai500.com/)

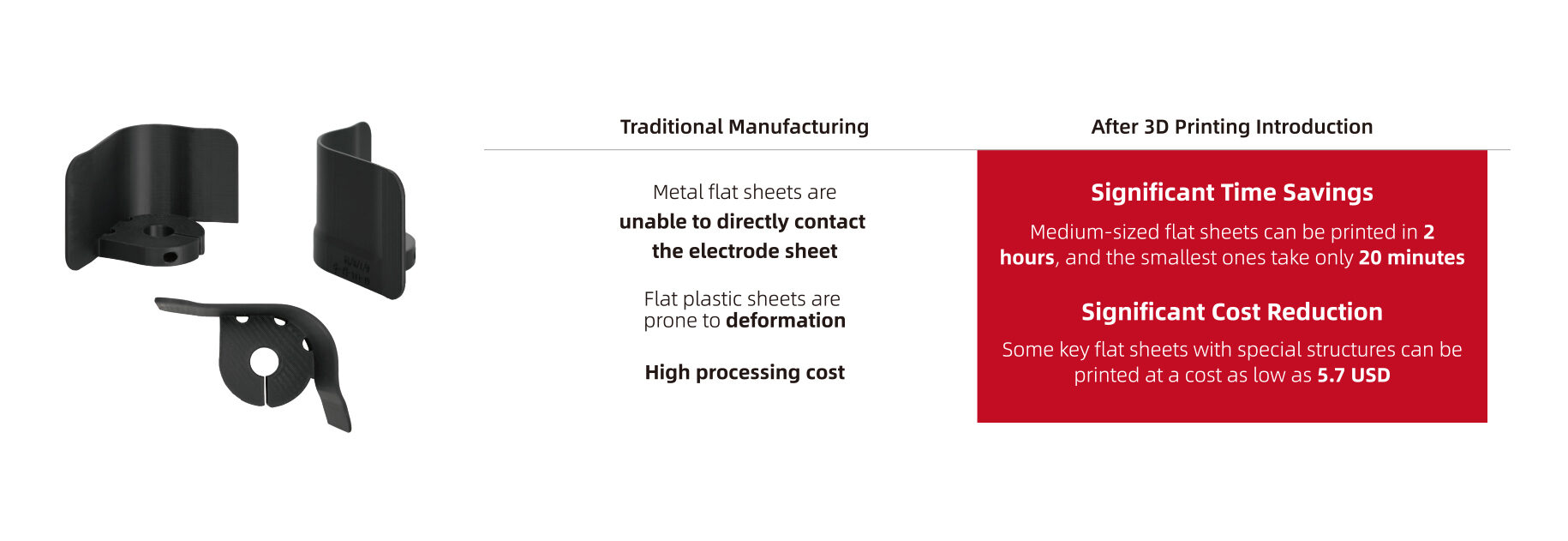

Traditional Manufacturing Methods Bring Innovative Challenges

As one of the world’s largest power battery manufacturers and an innovative pioneer in the field of new energy batteries, CATL has always been committed to technological breakthroughs in power batteries and energy storage systems.

CATL production scene (source: https://www.catl.com/news/846.html)

CATL production scene, highly automated PACK wire drawing (source: https://www.catl.com/news/6733.html)

Although CATL has a lot of innovation needs, in the battery cell assembly process, the traditional tooling and prototype verification production model cannot save costs while ensuring large-scale and rapid innovation iterations.

The traditional manufacturing model has the following limitations in terms of innovation in the battery cell production line:

- Slow response speed: Traditional CNC processing has a long delivery cycle, usually requiring 2-4 weeks to deliver, which seriously restricts the speed of product iteration.

- Limited design innovation: Manufacturing complex structures through traditional methods often involves many difficulties, such as tool customization and material limitations.

- Insufficient flexible production capacity: It is difficult to respond quickly to demands for multiple varieties and small batches.

- Long technology verification cycle: Low efficiency of fixture adaptation during new product development.

This model can no longer meet CATL’s rapid innovation needs. Therefore, how to break through the manufacturing bottleneck, optimize the manufacturing of fixtures and prototypes, and build a more flexible production system, has become a key issue for CATL’s technology upgrade.

Faced with these challenges, CATL urgently needs to establish an agile tooling and prototype manufacturing system that can support continuous innovation.

CATL production scene (source: https://www.catl.com/news/8247.html)