PPS CF

A top-performing composite filament for the most demanding applications

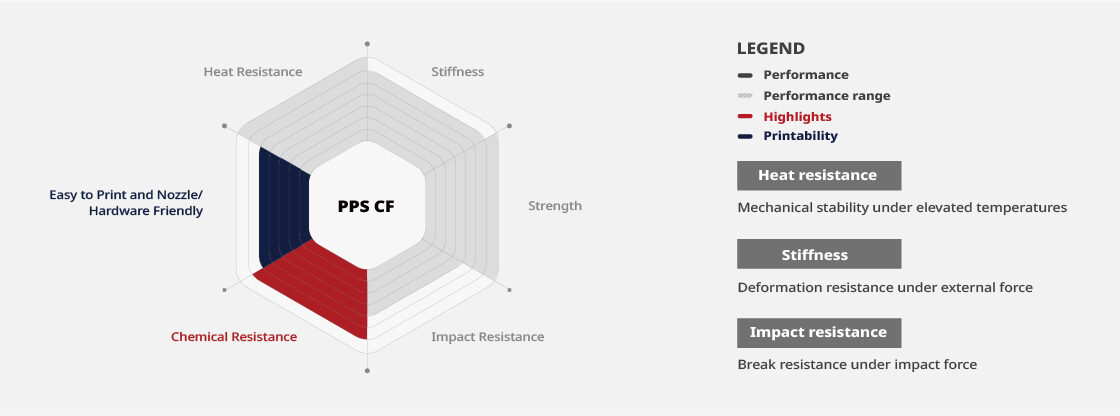

Raise3D Industrial PPS CF is a carbon fiber-reinforced (10 wt.%) polyphenylene sulfide (PPS) composite filament designed for high-performance applications. It stands out due to its peerless heat resistance (HDT 260°C) and chemical stability against corrosion from various acids, alkalis, and organic solvents. Additionally, PPS CF possesses excellent flame-retardant properties and is certified to meet the UL94 V0 standard. In terms of mechanical performance, final parts and components printed with PPS CF exhibit metal-like strength and rigidity, along with exceptional long-term dimensional stability and minimal moisture absorption. Notably, thanks to specially optimized carbon fiber distribution and length, PPS CF is highly compatible with unheated printing chambers and high-speed printing (L1: 150 mm/s, or faster up to L2), resulting in reduced warpage, smooth surface finishes, and less nozzle abrasion. Raise3D Industrial PPS CF is an ideal choice for industrial-grade applications, fulfilling all requirements for high-performance materials in terms of precision, reliability, and cost efficiency.

- High rigidity and strength

- Superior heat resistance (HDT over 250 °C)

- Ultra-low moisture absorption

- Dimensional stability and chemical resistance

- Hyper FFF® up to L2

Compatibility

Printer: Raise3D E3/ Raise3D Pro3 HS Series/ Raise3D E2CF/ Raise3D RMF500

Filament: Raise3D Industrial PET Support

Raise3D Industrial PPS CF Filament

Raise3D Industrial PPS CF Filament