Raise3D Strives to Pioneer Flexible Manufacturing

Raise3D is launching the Pro2 Series, a new series of printers developed with industrial-grade components, to enable the best possible Flexible Manufacturing solutions based on desktop 3D-printing systems.

Judging by its appearance, the Pro2 Series looks very much like the N2 Series printers, but we are talking about two completely different classes of printers.

The Pro2 Series printers are one of the fastest capable of dual printing, the accuracy is 16x higher than the market standard, with greatly improved usability, and its reliability will be a differentiating factor in the segment.

Even if the N2 Series has been acclaimed as a top printer in its category, a tremendous effort was made to take the Pro2 Series to the next level. We can confidently say that the new printers are the cream of the crop and are ready to forge a pioneering path in Flexible Manufacturing.

Why is Flexible Manufacturing so Important?

The quality of life during the 20th century improved as never before. Today, in most modern societies, people live longer and happier than before. The modernization of society has increased the demand for high-quality and low-cost products, for which mass production provided the answer.

But as mass production improved our lives, it came with a heavy burden: the need to always produce to a high standard and meet rigid process requirements. Due to mass production, it is very common to see people of different countries, cultures, lifestyle or beliefs using the exact same products, despite their deep cultural differences. This process happened much to the benefit of customers, who saw their purchase power growing rapidly and thus adapted to a more consumerist lifestyle.

However, over the last decade, several factors began changing the way we think and act. In contrast to the previous globalized thinking that was shaping society, we are now living a world of increasing individual expression, where most people want to and can express themselves as unique individuals. This process is creating a demand for exclusive and original products and experiences.

This rapid changing of consumer preferences puts the standard large and rigid batches required by mass production under heavy pressure. About 40 years ago, industries like steel or clothing already went through a process of reducing scales of production to gain a certain flexibility. But most manufacturing was still waiting for the disruption that could bring economic sense to smaller batch production.

The answer to this is now making itself more widespread with the general adoption of Additive Manufacturing (also known as 3D Printing) in traditional production processes.

Additive Manufacturing is making it possible to address a high level of customization at an advantageous cost and with excellent results. Additive Manufacturing can be used for rapid prototyping, for bridge manufacturing, and even for production, as it can often be by far the most convenient manufacturing option.

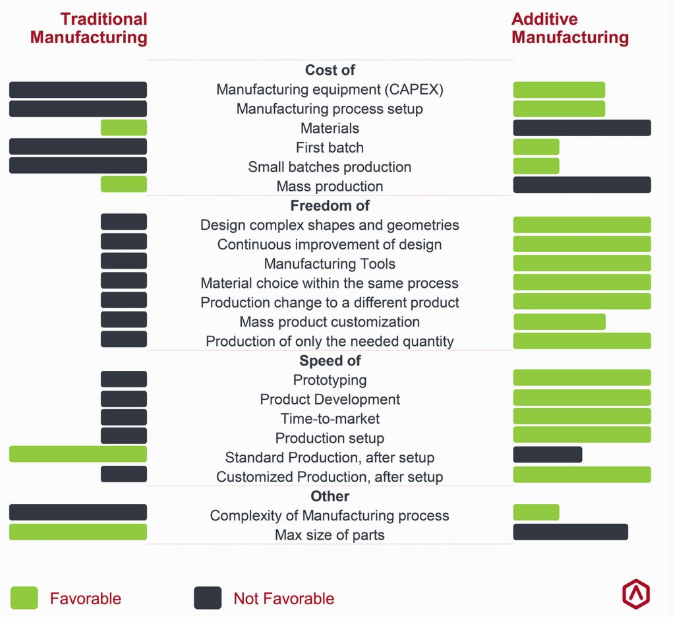

The business case for using Additive Manufacturing over traditional methods of production is clear[1]:

[1] This is a general analysis. The analysis may differ for a specific manufacturing process

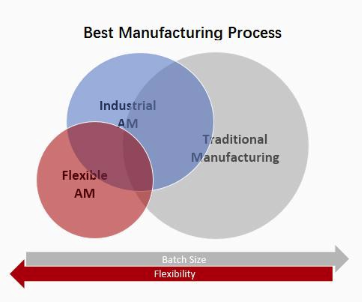

Over the coming years, traditional manufacturing is likely to remain as the option for high volume production that requires standardization. When it comes to lower-volume batches, however, 3D printers already beat traditional manufacturing – and the feasibility of a break-even batch size is rising.

Additive Manufacturing will undoubtedly play a significant role in the future of manufacturing. But there are still some barriers to overcome that, for now, may be slowing down more widespread adoption. Changing efficient and certified processes, like those of traditional manufacturing, entails a deep analysis of the alternatives, that requires:

- Knowing the existing product and process certifications;

- Understanding the implications of the whole manufacturing process;

- Knowing final product mechanical performance;

- Ensuring stability in the supply chain;

- Analyzing AQL data.

The Additive Manufacturing Industry is working on these factors, but they certainly remain a reason to withhold much of the change from happening, in particular when the initial cost to start using Additive Manufacturing is still somewhat high.

While we all move along this learning curve, there is one level of Additive Manufacturing that may soon facilitate and be part of that transition: Desktop FDM 3D Print Factories or, as we call it, Flexible Manufacturing.

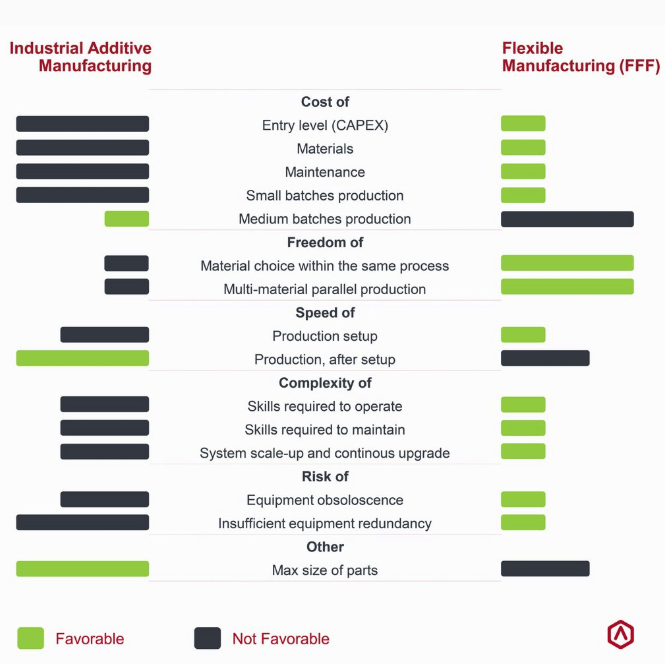

A Flexible Manufacturing system allows the creation of an affordable manufacturing capacity (from 50K USD), that can be efficient for batch sizes from a single unit up to a few thousand, and it’s easy to learn, easy to maintain, easy to upgrade and easy to scale-up.

Flexible Manufacturing pushes the advantages of Additive Manufacturing to the limit, by offering high flexibility also in terms of:

- Materials and colors used;

- Parallel production of parts of different materials;

- Parallel production of different batch sizes.

Besides playing a role of its own for lower batch sizes, Flexible Manufacturing can be a safe, low-risk entry to Industrial Additive Manufacturing.

Smart Manufacturing and Flexible Manufacturing

Flexible Manufacturing is also an essential component of Smart Manufacturing.

According to Deloitte University Press, “The smart factory is a flexible system that can self-optimize performance across a broader network, self-adapt to and learn from new conditions in real or near-real time, and autonomously run entire production processes. (…) The concept of adopting and implementing a smart factory solution can feel complicated, even insurmountable. However, rapid technology changes and trends have made the shift toward a more flexible, adaptive production system almost imperative for manufacturers who wish to either remain competitive or disrupt their competition.”

Also Agnieszka Radziwo, Arne Bilberga, Marcel Bogersa, Erik Skov Madsenb, in their paper “The Smart Factory: Exploring Adaptive and Flexible Manufacturing Solutions, define Smart Factory as “a manufacturing solution that provides such flexible and adaptive production processes that will solve problems arising on a production facility with dynamic and rapidly changing boundary conditions in a world of increasing complexity.”

So, Flexibility is a key driver for the Smart Factory.

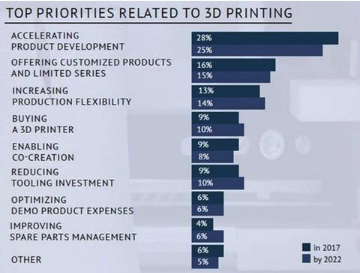

In Sculpteo’s “The State of 3D Printing – Edition 2017”, people who answers their questionnaire pointed out “offering customized product and limited series” and “increasing production flexibility” as top priorities regarding 3D Printing:

And according to a Jabil-sponsored 3D Printing Trends Survey, “Most manufacturing stakeholders (93%) report that they expect growth, including 38% that expect to at least double their use of 3D printing for production parts and 19% that expect their product use to increase dramatically by a factor of 5 or more.”

Being ready for Flexible Manufacturing will soon be a key competitive factor.

Are you prepared for the transition?

If you want to know how Flexible Manufacturing can create value for your Corporation, contact us to inquiry@raise3d.com