Reading Time: 23 Minutes

ABS was one of the first two plastics adopted for industrial 3D printers in the early 1990s, and it continues to shape how users think about printing with ABS today.

If you are running FFF or FDM systems, you will find ABS filament available almost everywhere, usually priced around $15–$50 per kilogram. That makes it an economical option for prototypes and short-run production, while specialty composites push the cost closer to $90 per kilogram.

Because it is petroleum-based yet fully recyclable, you need to plan ahead for end-of-life handling since recycling codes and drop-off options vary by region.

What keeps ABS relevant is not only its history but also its evolution: modern ABS-like resins for resin 3D printers now achieve injection molding–quality surface finish and balanced strength at print speeds measured in hours, broadening the range of ABS parts and applications.

What is ABS in 3D Printing?

ABS, or Acrylonitrile Butadiene Styrene, is one of the most widely used plastics in 3D printing. If you have worked with 3D printers, you’ve likely seen ABS filament mentioned as a standard material for functional parts and prototypes.

It is a terpolymer made by combining three monomers in specific ratios: roughly 20% acrylonitrile, 25% butadiene, and 55% styrene. Adjusting these percentages allows manufacturers to fine-tune properties such as rigidity, toughness, and impact resistance.

The polymer has an amorphous structure with a density around 1.04 g cm⁻³, which makes it lightweight yet durable. Because ABS is thermoplastic, you can repeatedly heat and reshape it without major degradation, an ability that supports both prototyping and recycling.

Its recyclability, however, depends on proper industrial streams, unlike bio-derived PLA which can sometimes enter composting systems. When comparing plastics, you’ll find ABS strikes a balance between heat resistance, mechanical strength, and affordability.

In printing, ABS parts benefit from controlled extrusion temperature and stable bed temperature to ensure layer adhesion and minimize warping. While PLA is often easier for beginners, ABS provides more professional-grade performance and closer alignment with materials used in injection molding, making it a reliable connection between prototyping and end-use production.

What are the Key Material Properties Of ABS?

Once you understand its chemical structure, the next step is looking at the physical and mechanical properties that make ABS prints valuable. These properties explain why ABS remains a popular material across industries, even with the rise of PETG and other modern filaments.

To maintain print quality, you need to balance extrusion settings, chamber conditions, and build platform adhesion, since each property is influenced by print environment.

Key properties of ABS include:

- Tensile Strength: ~38 MPa (ISO 527).

- Young’s Modulus: 2.1 GPa, giving a balance of stiffness and toughness.

- Glass-Transition Temperature: 105 °C, where the material softens.

- Heat-Deflection Temperature: 95–100 °C at 0.45 MPa, higher than PLA.

- Melting Onset (Amorphous Flow): ~200 °C, essential for extrusion control.

- Elongation At Break: 20–35%, allowing flexibility before failure.

- Impact Strength: 200–220 J m⁻¹ (Izod, notched), much greater than PLA.

- Density: 1.04 g cm⁻³, lightweight yet robust for engineering parts.

- Chemical Resistance: Resists dilute acids and alkalis but vulnerable to ketones.

- Surface Finish: Matte as printed, polishable with acetone or sanding for smoother finish.

Why Is It Used In 3D Printing?

ABS is used in 3D printing because it combines toughness, durability, and a favorable strength-to-cost ratio. When you print with ABS, you gain access to material properties that handle higher temperatures and mechanical stress better than PLA or PETG.

That means you can create gears, hinges, or parts exposed to repeated flexing without worrying about rapid fatigue.

Another reason is its versatility in post-processing. ABS parts can be solvent-welded for seamless assemblies, tapped for screw threads, or polished using acetone vapor smoothing to produce injection molding–like gloss.

This makes ABS prints suitable for cosplay items, consumer electronics enclosures, and product demonstrations where surface finish matters.

Compared with PLA, ABS oozes and strings less, which improves sidewall quality. Its compatibility with industry-standard injection molding grades also gives you a direct bridge from prototype models to production-ready items, making ABS a practical material when you need both functionality and scalability in your prints.

How Does ABS In 3D Printing Work?

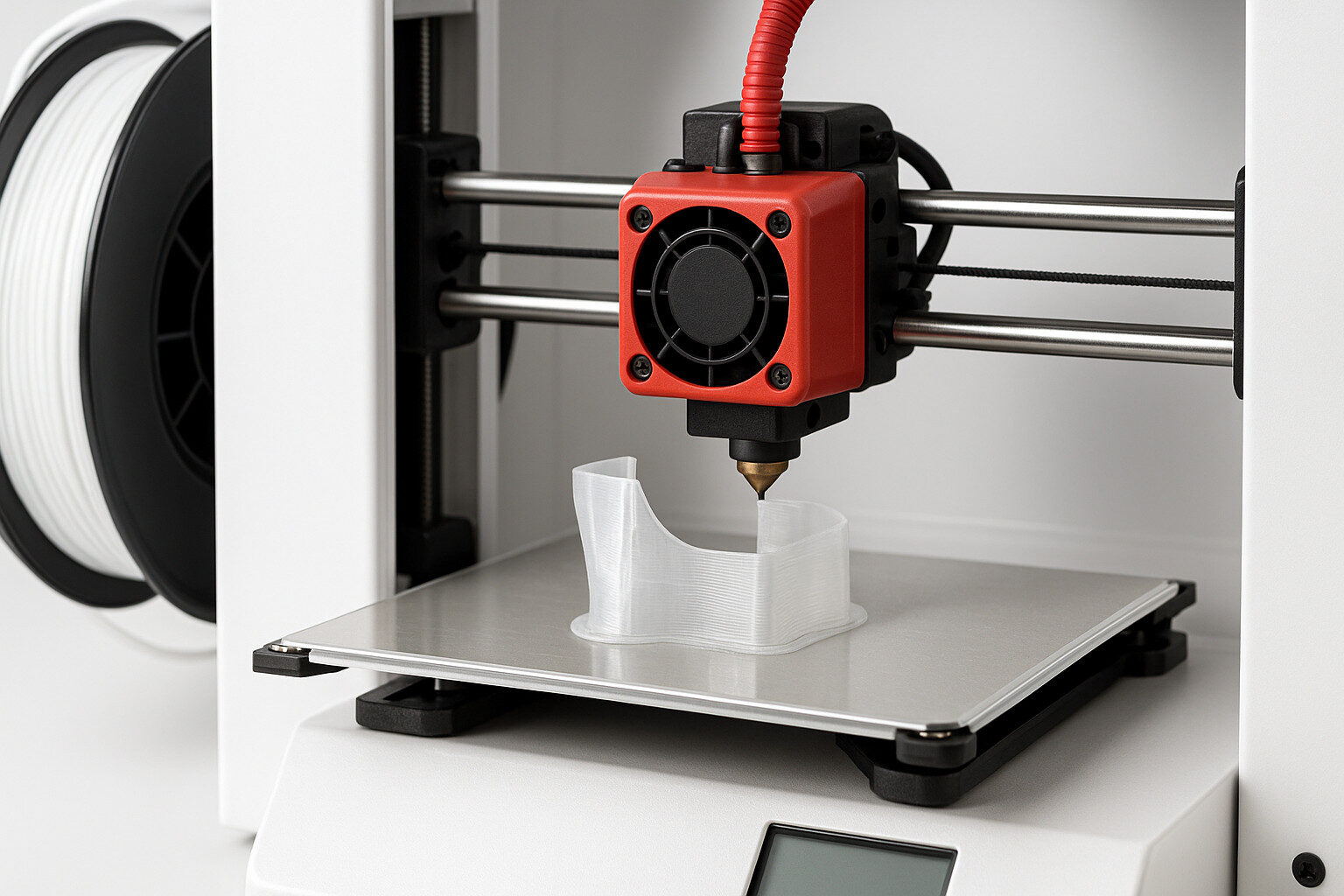

When you print with ABS filament, the process typically follows the fused filament fabrication (FFF) or fused deposition modeling (FDM) method.

A spool of 1.75 mm or 2.85 mm filament is fed into the extruder, heated to an extrusion temperature between 220 and 260 °C, and pushed through a nozzle that lays down thin layers of molten plastic. Each layer is deposited onto a build surface, usually held at a bed temperature of 95–110 °C, which prevents warping and secures strong layer adhesion.

The role of the heated chamber or enclosure is critical. By maintaining a steady ambient temperature, you reduce stresses that cause cracks or separation between layers.

At the same time, you need to fine-tune the cooling fan settings because too much airflow can weaken bonds, while too little can affect overhangs or bridging.

Balancing these conditions ensures that your ABS prints have the durability and surface finish you expect.

Dual-extrusion workflows make ABS even more versatile. With a second nozzle, you can use soluble HIPS supports or even low-adhesion PLA as breakaway structures, enabling complex geometries and smoother results.

Each of these steps demonstrates how extrusion temperature, chamber control, and material choice connect directly to print quality and performance when printing ABS parts.

What Are The Different Types Of ABS In 3D Printing?

Although standard ABS remains the most common choice, several modified grades have been developed to address specific issues such as warping, heat resistance, or flame security.

Standard ABS is valued for balance: it offers strength, durability, and good impact resistance at a reasonable cost.

PC-ABS, a polycarbonate blend, enhances the heat deflection temperature (HDT) to around 110–120 °C and adds UL-94 V-0 flame-retardant properties, making it a reliable material for enclosures that need better fire safety.

You will also find composite grades. ABS reinforced with Kevlar fibers improves toughness for applications where repeated stress or vibration is expected.

ABS-carbon-fiber reduces shrinkage by roughly 30% while increasing stiffness, though it requires hardened nozzles due to abrasive fibers.

Flame-retardant ABS variants meet higher safety standards, while bio-based ABS incorporates recycled feedstock to reduce environmental impact.

Each of these types addresses issues users encounter when printing ABS, from warping to fumes, and opens up applications in automotive, electronics, and functional prototypes.

What Are ABS Composite Filaments And When Should You Use Them?

Composite ABS filaments extend the material’s capabilities by blending fibers or additives that improve performance. If you need stronger and more dimensionally stable ABS prints, carbon-fiber ABS is a strong candidate.

It offers a roughly 15% boost in tensile modulus and shrinks less during cooling, which helps reduce trouble with warping on the build plate. The trade-off is that its abrasive fibers will wear down a standard brass nozzle, so a hardened steel nozzle is recommended.

Another common variant is flame-retardant PC-ABS. By incorporating self-extinguishing additives, this blend provides both heat resistance and security against fire, making it suitable for electronics housings and products that must meet UL-94 requirements.

Choosing these blends depends on your project’s connection to performance: if you want impact resistance, stiffness, or safety certification, a composite filament may be the right choice. With proper settings and the right printer features, reinforced ABS gives you benefits beyond standard grades and helps expand what you can build with confidence.

What’s The Difference Between Real ABS And Modified ABS?

Real ABS refers to the classic terpolymer of acrylonitrile, butadiene, and styrene in well-established ratios. This form is tough, heat resistant, and remains closest to the plastic used in injection molding. Modified ABS, on the other hand, introduces additives such as acrylic or elastomer modifiers.

These changes allow you to print at a slightly lower extrusion temperature, often around 210 °C, which helps open-frame 3D printers manage the material without excessive warping. The trade-off is that heat deflection temperature and stiffness are reduced compared with standard ABS.

Still, for users seeking easier handling and lower chamber requirements, modified ABS provides a practical choice. By balancing ease of use with mechanical performance, you can decide whether pure or modified ABS better suits your applications.

What Are ABS-Like Resins And How Are They Used In Resin Printing?

FFF is not the only way to achieve ABS parts. In resin-based 3D printing, you can turn to ABS-like resins designed for SLA and DLP technologies.

These resins mimic many mechanical features of ABS while delivering smoother surface finish because they avoid the visible layer lines of FFF. Typical ABS-like resins reach tensile strength values around 60 MPa, with a modulus of 2.5 GPa and a heat deflection temperature near 80 °C.

That combination makes them suitable for small precision parts, functional prototypes, and housings where surface quality is as important as strength. When you are looking for dimensional accuracy without the odors, fumes, and warping risks of printing ABS filament, ABS-like resins offer a clear alternative.

They extend the reach of ABS materials beyond the build plate and into high-resolution resin printing.

What Are The Different ABS Filaments On The Market?

When shopping for ABS filament, you’ll see a wide range of choices in price, color, and performance.

Standard grades usually fall in the $15–$50 per kilogram range, while composite versions such as CF-ABS or PC-ABS climb to $45–$90 per kilogram.

Most manufacturers now offer ±0.02 mm diameter tolerance and ship spools in vacuum-sealed bags with desiccant to protect against moisture uptake.

- MH Build ABS: $18.21 in bulk: reliable for general-purpose use, easy for dialing in printer settings, and available in many colors.

- PRO Series ABS: $52 per kg: made in the USA with ±0.02 mm tolerance; large spools for heavy users.

- Ultimaker ABS: $50 per 750 g: integrates with Ultimaker printers through NFC recognition, only in 2.85 mm.

- eSUN ABS: $23 per kg: affordable, general purpose, with a variety of colors for everyday printing.

- Fillamentum ABS: $45 per 750 g: premium Czech-made filament with unique translucent color options.

- 3DXTech Flame Retardant PC-ABS: $68 per kg: blends PC strength with ABS handling, self-extinguishing for safety-critical parts.

- Raise3D ABS Filaments: offered in consistent diameters, designed for secure connection with Raise3D printers, and packaged for long-term storage.

What Common Applications For ABS 3D Printed Parts And Components?

ABS is one of the most widely used plastics in 3D printing because it delivers strength, durability, and surface finish suitable for both prototypes and end-use parts.

You’ll find ABS prints in industries ranging from automotive to consumer electronics, where its heat resistance and toughness make it a dependable material. Compared with PLA or PETG, ABS filament produces items that withstand real-world conditions such as friction, heat, and impact.

Here are some of the most common applications you can achieve when printing with ABS:

- Automotive Interior Clips, Phone Mounts, Cup-Holders: heat stable to about 80 °C, suitable for daily use inside vehicles.

- Robot Frames & Functional End-Effectors: impact-tough parts that handle repetitive motion.

- Voron Core-XY Printer Structural Parts: rigid components supporting open-source printer builds.

- Cosplay Helmets & Props: acetone-smoothed to achieve glossy, injection molding–like finish.

- Consumer Electronics Housings: chemical-resistant, easily painted for professional finish.

- Jigs, Fixtures, And Soft Jaws: durable workshop tools for holding or aligning parts.

- Protective Gear Shells: skateboard helmets and other gear requiring shock resistance.

- Educational Kits & Lego-Style Blocks: accurate items that demonstrate tolerance stacking.

These examples highlight how ABS parts provide a reliable connection between functional testing and final product performance.

How To Prepare For Printing With ABS?

If you want consistent print quality with ABS, preparation is one of the most important steps. ABS filament absorbs moisture, and if you skip drying, you risk hearing pops during extrusion or seeing bubbles and weak layers.

- Always dry filament at about 80 °C for four to five hours before loading it. This single action improves surface finish, strength, and layer adhesion.

- Next, think about temperature stability. Preheat the printer’s build chamber to 45–60 °C before starting a job. Warming the enclosure reduces warping by minimizing temperature fluctuations.

- You should also preheat the print bed to its target value, usually between 95–110 °C, to ensure the first layer bonds well to the build surface.

By combining proper drying, chamber heating, and bed preparation, you create the conditions for reliable ABS prints.

Skipping any of these steps often leads to trouble like layer separation or poor adhesion. Once these preparations are done, your printer is ready to handle ABS confidently.

What Printer Features Are Required For ABS Printing?

Not every printer can handle ABS. To manage the extrusion temperature range of 220–260 °C, your setup should include an all-metal hotend capable of sustained high temperatures. For users working with carbon-fiber ABS or other abrasive grades, a hardened nozzle is also necessary to avoid premature wear.

A heated print bed is essential to keep the build plate at 95–110 °C. Without it, warping is almost guaranteed. An enclosed chamber is another critical feature, since it keeps the ambient temperature stable and prevents drafts from disrupting prints.

Finally, ventilation or filtration should not be overlooked, because ABS fumes can produce an odor and release ultrafine particles.

By ensuring your 3D printer has these features, you gain both performance and security. These hardware choices reduce issues such as layer adhesion failure, warping, or weak ABS parts, giving you reliable results for a wide range of applications.

How Should ABS Filament Be Stored And Handled?

ABS is hygroscopic, which means it readily absorbs moisture from the air. If you don’t store it correctly, the filament gains weight, creates bubbles during extrusion, and produces weak ABS prints with poor layer adhesion. You should always keep ABS filament in a sealed dry-box at less than 15% relative humidity. This simple step helps maintain print quality and protects against warping and surface defects.

Another way to check for moisture is by monitoring spool weight. If your filament feels heavier than expected, that is often a sign of water uptake. Drying the spool at 80 °C for several hours before printing can restore performance. By treating storage as part of your workflow, you maintain consistent extrusion temperature, smooth surface finish, and dependable ABS parts.

Proper Printer Calibration And Setup

Printer calibration is essential when printing with ABS because this material responds strongly to heat and surface conditions. You should start by performing mesh-bed-leveling at the actual operating bed temperature—95 °C or higher. Heating the build plate before calibration compensates for thermal expansion of sheets and ensures reliable first-layer connection.

Nozzle height also matters. If it is too high, adhesion fails, leading to warping and wasted material. Too low, and you risk dragging plastic across the build surface. A priming skirt or brim can help you confirm extrusion flow and stability before the main print begins. Taking time to calibrate settings reduces trouble later and improves print quality for every ABS part.

How To Choose The Right ABS Filament?

Choosing ABS filament is about more than color or cost. Standard spools work well for general parts, but modified versions give you specific benefits. Flame-retardant ABS carries UL 94 certification for added security in electronics. Impact-resistant grades withstand repeated stresses. Carbon-fiber ABS provides stiffness and reduced warping, though it requires a hardened nozzle.

When selecting a brand, review technical information such as heat deflection temperature, glass transition temperature, and tolerance reports. Many premium suppliers include batch data, ensuring consistent extrusion diameter and predictable results. Color stability also matters if you plan to paint or finish the parts. By checking these details, you can match filament properties with your application needs, whether that means cosplay props, machine shop fixtures, or functional enclosures. The right choice gives you confidence that your ABS prints will perform as expected.

What Are The Optimal Print Settings For ABS?

Getting reliable results when printing with ABS depends on choosing the right print settings. Unlike PLA, ABS requires higher extrusion temperature, a stable print bed, and a controlled enclosure to minimize warping and ensure layer adhesion.

Every printer behaves a little differently, so it’s not enough to rely on generic numbers. You should treat each spool of ABS filament as unique, since variations in color, additives, and even storage conditions can change how it performs.

A practical way to dial in the right parameters is to run a temperature tower test whenever you open a new spool. This gives you clear information about extrusion temperature and surface finish across a range of settings. Pair it with a retraction test to prevent stringing and secure clean ABS prints.

By approaching settings as a systematic guide rather than guesswork, you not only improve print quality but also reduce wasted filament and troubleshooting.

When you balance extrusion temperature, bed temperature, chamber heat, and cooling fan use, your ABS parts achieve both strength and finish suitable for functional applications.

What Is The Ideal Extruder Temperature For ABS?

The extruder temperature is one of the most critical settings when printing ABS. You should keep it in the 220–250 °C range, depending on your printer and the specific brand of ABS filament. A good starting point is around 235 °C, then fine-tune in ±5 °C steps.

If the extrusion temperature is too high, you will notice strings, blobs, and a rough surface sheen. On the other hand, printing too cold leaves dull lines, poor surface finish, and weak layer bonding.

Finding the right midpoint ensures that ABS parts maintain strength and layer adhesion while preserving print quality. Running a quick calibration print is the best way to confirm whether your chosen temperature delivers consistent results across layers and avoids issues like warping.

Nozzle Temp

In 3D printing, nozzle temperature is the same as extruder temperature. When you are working with ABS, both terms describe the heat applied at the tip of the hotend where the filament is melted and deposited. For most users, 220–250 °C covers the required range, but the right number depends on your brand of filament, extrusion speed, and cooling fan settings.

If you plan to print advanced grades such as PC-ABS, an all-metal hotend is strongly recommended. Unlike PTFE-lined hotends, all-metal designs tolerate temperatures up to 260 °C without degradation. This extra capacity adds security and extends the capabilities of your 3D printer, especially if you experiment with reinforced ABS blends. By treating nozzle temp as a key variable, you give yourself more control over layer adhesion, surface finish, and the long-term performance of your ABS prints.

What Bed Temperature Should Be Used For ABS?

Bed temperature plays a crucial role when printing with ABS because it directly influences adhesion and reduces warping. Most 3D printers handle ABS best with a heated print bed set between 95–110 °C. This temperature range prevents shrinkage stresses that can cause the first layers to pull away from the build plate. For thinner parts with low wall thickness, you may find success at around 90 °C. On the other hand, thicker models over 10 mm benefit from higher settings, often closer to 110 °C or more, to keep layer adhesion secure.

Maintaining the right bed temperature ensures ABS parts hold firmly to the build surface and produce consistent print quality. Combined with adhesion aids like a brim or glue stick, this approach minimizes failed prints and improves the surface finish of your final product.

What Print Speeds Work Best For ABS?

ABS requires balanced print speeds to achieve both strength and quality. A general range of 30–60 mm/s works well, but how you apply it matters. Keep the first layer speed at or below 30 mm/s to maximize adhesion and give the filament enough time to bond with the build platform. Once the foundation is solid, you can increase speeds for infill and perimeters. Speeds up to 60 mm/s are possible if your chamber temperature is stable and your printer maintains consistent extrusion.

Moving too fast leads to poor layer adhesion and reduced impact resistance, while moving too slow can exaggerate heat buildup and create surface defects. By adjusting speed according to part geometry and chamber conditions, you keep ABS prints reliable while optimizing build time.

Should You Use Cooling Fans While Printing ABS?

Cooling fan settings require careful attention when printing ABS. Unlike PLA, ABS does not benefit from heavy cooling because it makes layers contract too quickly and causes delamination. For most prints, you should keep the part-cooling fan turned off or set at no more than 10%. This limited airflow is enough to support bridges or overhangs without disrupting inter-layer connection.

Excessive cooling creates splits, weakens the material, and increases the risk of warping. By contrast, a warm enclosure combined with minimal fan use maintains the heat resistance and durability ABS is known for. With the right balance, you get stronger ABS parts, smoother surfaces, and fewer print failures.

What Layer And Wall Settings Are Recommended For ABS?

When you are printing ABS, layer height and wall thickness control both the strength of the part and the appearance of the surface finish. A typical layer height of 0.2 mm strikes a balance between print quality and build time. It allows most 3D printers to create ABS parts with strong layer adhesion while maintaining detail. If your goal is to make cosmetic models where finish matters more than speed, you can lower the layer to 0.1 mm.

For wall thickness, three perimeters with a 0.4 mm nozzle—equal to about 1.2 mm total—provide security against splitting and improve impact resistance. This extra material along the perimeter is especially valuable when parts are exposed to stress or need durability close to injection molding quality.

Just as layer settings improve adhesion, adhesion aids also matter. That takes us into the role of brims, rafts, and supports in stabilizing ABS prints.

How Do Brims, Rafts, And Supports Help With ABS Prints?

ABS filament shrinks as it cools, and this creates a constant risk of corner lift and warping. By increasing the contact area between the part and the build surface, brims and rafts act as a stabilizing tool. A brim with a width of about 6–10 mm around the footprint of your model gives the print bed more grip, reducing edge curling. Rafts go one step further by adding a sacrificial base layer that isolates the part from small imperfections on the build platform.

Supports are equally important. When overhangs or bridging appear in your design, properly tuned supports maintain connection between layers without compromising print quality. You can improve the surface finish of critical parts by carefully removing supports after cooling. Together, these tools protect your ABS prints from early detachment, giving users a more reliable way to achieve results.

Once adhesion tools are in place, slicer settings become the next adjustment point for printing ABS effectively.

Which Slicer Settings Should Be Adjusted For ABS?

Tuning slicer parameters gives you control over the fine details of ABS printing. Retraction is one of the first things to set. A retraction distance of 3–4 mm at around 40 mm/s helps reduce stringing while keeping extrusion temperature stable. This ensures that filament moves smoothly without leaving unwanted threads across the print.

For shells, three outer perimeters create enough wall thickness for durability without adding unnecessary cost in extra filament. Infill percentage between 25–40% provides strength for functional ABS parts while limiting shrinkage stresses that cause warping. Using a grid or gyroid infill pattern balances strength and resistance to deformation.

Adjusting these settings in combination with the right chamber temperature, cooling fan limits, and adhesion strategies allows you to produce ABS prints that rival the strength and performance of injection molding in many cases.

ABS Print Settings Reference Table

| Configuration Setting | Recommended Value/Range | Notes/Benefits |

| Extrusion Temperature | 230–250 °C | Ensures flow above glass transition temperature for layer adhesion |

| Bed Temperature | 95–110 °C | Higher temps prevent warping on thicker walls |

| Nozzle Size | 0.4 mm (standard) | Good balance of detail and speed |

| Layer Height | 0.2 mm (0.1 mm for cosmetics) | Lower layer = better surface finish |

| Wall Thickness | 1.2 mm (3 perimeters) | Improves part strength and security |

| Print Speed | 30–60 mm/s | First layer ≤ 30 mm/s for adhesion |

| Retraction Distance | 3–4 mm | Minimizes stringing issues |

| Retraction Speed | 40 mm/s | Smooth filament pull-back action |

| Infill Percentage | 25–40% | Balances strength and cost |

| Cooling Fan Speed | 0–10% | Limited use avoids layer separation |

| Adhesion Aid | 6–10 mm brim / raft optional | Reduces warping, improves stability |

| Enclosure Temperature | 45–60 °C | Maintains heat resistance and finish |

What Are the Limitations of ABS Filament?

Warping is the most common issue: as the material cools below its glass transition temperature, the layers contract and pull upward from the build surface. This leads to curled corners, failed prints, or compromised layer adhesion if your print bed is not properly conditioned.

Another factor is odor and fumes. When printing ABS, the extrusion temperature generates styrene VOCs and ultrafine particles. Long exposure without ventilation may cause headaches, nausea, or respiratory irritation.

That’s why many best practices include printing with an enclosure, using air filtration, or ensuring adequate ventilation.

You will also find that ABS is less forgiving than PLA on bare build plates. Without adhesion aids like glue stick, tape, or ABS slurry, bed adhesion can become inconsistent. Users often report trouble with larger parts where the build platform simply cannot counter the stress.

These challenges don’t mean you should avoid ABS prints, but they do highlight the need for correct settings, a stable environment, and attention to health security when working with this material.

How To Create a Stable Printing Environment for ABS?

To get consistent results when printing ABS, you need more than just the right extrusion temperature or print speed. The environment around your 3D printers plays a decisive role in print quality. ABS parts are sensitive to drafts, sudden temperature shifts, and poor chamber control, which can quickly undermine layer adhesion.

Creating a stable environment reduces warping, enhances surface finish, and ensures that your ABS prints look closer to injection-molded plastic parts.

Think of your print chamber as the foundation of success. A warm and enclosed build platform environment keeps the layers above the glass transition temperature long enough for secure bonding.

The right chamber settings also improve connection between walls and infill, protecting against cracks or delamination. Without this, even perfect slicer settings will struggle to deliver.

Users often underestimate the impact of environmental conditions, but ABS requires careful balance. You need consistent bed temperatures, limited cooling fan use, and insulation from external airflow.

Enclosures are a primary way to secure these conditions, and whether purchased or built DIY, they make a noticeable difference in ABS performance. Before focusing on fine slicer adjustments, it’s best to lock down your chamber conditions so that every action taken with settings delivers predictable results.

Why Is an Enclosure Important When Printing ABS?

An enclosure is one of the most effective tools for managing ABS printing issues. Unlike PLA or PETG, ABS filament shrinks significantly as it cools, and open-air conditions encourage warping and delamination. An enclosure stabilizes the print chamber, trapping heat and protecting the print bed from ambient drafts. This makes a direct impact on layer adhesion, surface finish, and overall print quality.

The ideal chamber temperature for printing ABS is between 45–60 °C. Many users create DIY enclosures from IKEA Lack tables and polycarbonate sheets, while others use professional-grade chambers integrated into advanced printers. The goal is the same: prevent temperature fluctuations that compromise part security. With stable conditions, you can print larger ABS parts, reduce fumes drifting into your workspace, and achieve results much closer to commercial-grade plastic applications.

How Should You Ventilate When Printing With ABS?

When you are printing with ABS, ventilation is not optional—it’s a matter of health security. At the extrusion temperature needed for ABS filament, the material releases fumes containing styrene VOCs and ultrafine particles. These can cause headaches, nausea, or discomfort with long exposure, so you need a safe way to handle them. The best practice is to place your 3D printers inside a closed enclosure fitted with both a HEPA filter and an activated-carbon stage. This combination captures particulates while removing odor from the air.

For even greater protection, connect an inline duct fan and exhaust outdoors through a window or vent. That way you protect indoor air quality without sacrificing print quality. With the right action on ventilation, you avoid health issues while keeping your ABS prints consistent.

What Room Conditions Improve ABS Print Success?

Ventilation is only one part of creating the right environment. Room conditions also determine how stable your ABS prints will be during long jobs. If the ambient temperature drops below 20 °C, the build surface cools too quickly, reducing layer adhesion and increasing chances of warping. Keeping your printer in a warmer, stable room helps maintain consistent bed temperature and prevents defects.

Equally important is isolating the printer from HVAC vents, drafts, or air-conditioning units. Even small bursts of air can disrupt the chamber environment and lead to trouble with ABS parts lifting from the build plate. A closed room with controlled airflow gives you more predictable results. When you combine enclosure, filtration, and careful room management, you create conditions that maximize surface finish and print quality for ABS filament.

How to Ensure Good Bed Adhesion When Printing ABS?

Good bed adhesion is the foundation of successful ABS prints. Without a solid first layer, you deal with warping, lifted corners, and wasted filament. ABS has a higher glass transition temperature than PLA or PETG, which means it shrinks more as it cools. This shrinkage creates tension between the print bed and the part, often leading to failed jobs if not addressed. That’s why you need to take deliberate action when preparing your build platform.

A heated bed set to the right temperatures helps reduce stress during cooling. Adhesion aids such as a glue stick, ABS slurry, or a brim add another layer of security against lifting. When combined with a clean build surface and the right printer settings, these steps create a strong connection between the first layer and the bed. Getting this step right improves print quality, strength, and finish of ABS parts.

How to Properly Calibrate the First Layer for ABS?

The first layer is where your ABS filament establishes contact with the build plate, and calibration is key to success. Start by adjusting your Z-offset so the nozzle is close enough to slightly squash the extrusion against the surface. This helps maximize layer adhesion without restricting flow.

Dial in your flow rate to ensure you are not under-extruding or over-extruding. Too little, and the print will peel away; too much, and you’ll create excess material that ruins the surface finish. A reliable way to stabilize extrusion is to add a priming skirt of two or three outlines before the first layer begins. With these adjustments in place, your ABS prints gain consistency and strength.

Which Print Surfaces Work Best for ABS?

The build surface you choose determines how well ABS sticks to the print bed. Some consumables are more effective than others, and the right choice depends on your printer setup. PEI sheets are among the best options, offering both durability and strong adhesion while leaving a glossy finish on the bottom of ABS parts. BuildTak and Kapton tape provide excellent grip at high extrusion temperatures, though each has its own cost and wear considerations.

Glass with an adhesion spray is another common choice, giving a smooth finish but requiring extra care to avoid warping. PET tape works as a low-cost alternative that can still deliver good results for users on a budget. Each surface has benefits and cons, but with the right temperatures and best practices, you can secure reliable adhesion across a variety of applications.

What Adhesion Aids Help ABS Stick to the Bed?

When you are printing ABS filament, adhesion is one of the first challenges you encounter. The material contracts strongly as it cools from extrusion temperature down toward its glass transition temperature, and that tension can lift parts off the build platform. To counter this, users rely on consumables that create a stronger connection between the build plate and the first layer. A simple glue stick is often enough for small parts, while hairspray or Magigoo provide an even coating that increases security for larger items.

One of the most effective methods is ABS slurry: dissolve 10 g of scrap ABS in 100 ml of acetone and brush on a thin film. The surface finish may not be as glossy as PEI sheets, but the results reduce warping and improve print quality. Each option has its own cost, odor, and performance features, so testing different aids helps you find the best practices for your printer setup.

What Are the Necessary Post-Processing Techniques for ABS Prints?

Working with ABS filament does not end when the print bed cools. Post-processing is an essential step that transforms raw ABS prints into finished, functional parts. You begin by waiting for the printer and build platform to reach safe temperatures, then carefully remove the part from the bed without forcing it. If you act too soon, you risk warping or breaking the connection at weak layers. Once removed, cleaning the surface of excess brim or raft material is the next action, and this improves both fit and surface finish.

ABS prints often benefit from extra steps to achieve strength and appearance close to injection molding. Cooling fans should be avoided at this stage since uneven airflow can cause cracks. Instead, controlled cooling inside an enclosure or chamber maintains the security of the layers. After cleaning, you can decide whether sanding, polishing, or chemical smoothing provides the best results for your application. Each method has different benefits and costs, but all contribute to higher print quality and performance.

How to Sand and Polish ABS Prints?

Sanding ABS parts is one of the most reliable ways to improve surface finish. Start with a coarse grit to even out rough features, then gradually move toward finer grits using a wet sanding method. A typical workflow goes from 150-grit to 320, then 600, and finally 1000-grit for a smoother layer transition. Wet sanding minimizes dust and reduces odor while keeping the material cool.

After sanding, polishing compounds such as Brasso or Novus #2 bring out a glossy finish that rivals professional plastic products. This process requires patience, but users find that it enhances both appearance and touch. Once you learn the technique, sanding and polishing become essential tools for printing ABS with consistent quality.

How Does Acetone Vapor Smoothing Work for ABS?

Another common way to finish ABS prints is acetone vapor smoothing. The principle is simple: acetone dissolves the outer layers of ABS filament, creating a glossy finish. You begin by placing the part inside a sealed enclosure above a shallow source of acetone. Gentle heating should never exceed 60 °C, since acetone has a low flash-point and generates flammable fumes.

As vapor rises, it reacts with the surface of the ABS print, softening outer layers and allowing them to level out. The process usually takes a few minutes, and waiting too long can damage the size or details of the product. Good ventilation or a fume hood is necessary to avoid trouble with odor and safety issues. When done correctly, vapor smoothing creates an even surface finish and increases resistance to moisture and wear, giving ABS parts a professional look and durable performance.

How to Remove Support From ABS Prints?

Removing supports from ABS prints requires patience and the right method to protect surface quality. You can trim standard support structures with pliers or a sharp blade, but avoid forcing pieces away too soon or you may damage the print. If you printed with HIPS as a support material, the process is easier. HIPS dissolves in D-Limonene, which allows hands-free removal without leaving tool marks on the ABS surface.

The recommended workflow is an eight-hour bath in D-Limonene at around 40 °C. During this waiting period, the HIPS breaks down while the ABS part remains intact. This method reduces odor, avoids trouble with stress cracks, and preserves print quality. By combining good chamber ventilation with careful handling, you improve both finish and strength for your final product. Transitioning from clean support removal, you can now consider the aesthetic side of ABS applications.

Can ABS Prints Be Painted or Finished?

ABS has a natural matte plastic look, but you can upgrade its appearance with paint. The first step is proper surface preparation, which includes sanding to eliminate visible layers and imperfections. Once smooth, apply an acrylic sandable primer to create a strong base for color coats. After priming, wet-sand the surface with 600-grit paper to achieve a uniform texture that enhances adhesion and finish quality.

With the surface ready, you can spray color coats in thin layers, waiting for each to dry before applying the next. Users often apply clear coats for extra durability and resistance. Painting ABS prints is a way to bring design features closer to the polished look of injection molding, while still taking advantage of the flexibility of 3D printers. Once painted, your parts achieve both functional performance and a professional surface finish. Moving from appearance, you may also need to join multiple items together for larger assemblies.

How to Join or Assemble ABS Multi-Part Prints?

When a project requires ABS parts larger than your print bed, joining becomes necessary. One common method is solvent welding, where you apply ABS glue (scrap ABS dissolved in acetone) or use methylene chloride for stronger bonds. These solvents soften the material at the connection points, fusing the layers into a single solid structure. This technique is often used in applications where structural security and strength are important.

For smaller assemblies, you can tack-weld edges with a 3D pen loaded with ABS filament. This adds extra reinforcement and reduces the chances of failure at stress points. In cases where precision is needed, clamping the parts together while the solvent cures ensures a clean finish. Ventilation is critical, as fumes from solvents can be irritating. By combining welding, bonding, and finishing methods, you can create complex ABS models with the durability and appearance of professionally produced plastic items.

What Software Tools Are Best For Slicing ABS Prints?

When you are printing with ABS, the slicing software has a direct impact on print quality, layer adhesion, and overall performance. Popular tools like Cura, PrusaSlicer, Simplify3D, and MatterControl give you detailed control over extrusion temperature, bed temperature, cooling fan behavior, and chamber features. Cura is widely used because of its balance between accessibility and advanced settings, and its draft-shield feature helps warm the edges of tall ABS prints, reducing warping. PrusaSlicer offers user-friendly ABS profiles with fine-tuned presets for glass transition temperature and bed adhesion. Simplify3D provides detailed control over support placement and surface finish.

MatterControl stands out with its built-in temperature-tower generator, allowing you to dial in the best settings for your ABS filament. Each of these programs offers plugins and guides that improve results, reduce trouble with fumes, and ensure your ABS parts maintain strength and professional surface finish. Once slicing is optimized, the focus shifts toward solving practical printing issues.

What Are Common ABS Printing Issues And How To Fix Them?

The main issues when printing ABS are warping, poor layer adhesion, odor from fumes, and surface finish inconsistencies, but each problem has proven solutions.

Warping is often caused by temperature fluctuations, so increasing the bed temperature, applying ABS slurry, or printing inside an enclosure reduces curling. For layer adhesion issues, you can raise the extrusion temperature, check filament quality, or slow down print speed for better bonding between layers.

If you encounter odor and ventilation trouble, using an enclosed chamber with activated carbon filters improves air quality while maintaining security of the print environment.

Another common issue is parts detaching from the build surface, which can be solved with a glue stick, PEI sheet, or painter’s tape. Bed leveling and waiting for the build plate to reach the correct temperatures improve consistency.

In addition, enabling features like a brim or draft shield increases the chances of success for tall items. Once you understand these challenges, you can focus on preventing the most frequent issue of all: warping.

How To Prevent Warping And Curling?

Warping and curling in ABS prints occur when the material cools unevenly, shrinking at the edges and lifting off the build plate. The main reason is a large temperature gradient between the print bed and the surrounding air.

To fix this, keep your bed temperature between 100–110 °C, print inside an enclosure, and avoid excessive cooling fan use. Applying ABS slurry, a glue stick, or PEI sheets also improves adhesion to the build surface.

For tall ABS parts, enable both the “brim” and Cura’s “draft shield” feature. The brim increases contact area on the build platform, while the draft shield warms the edges during printing, reducing the impact of airflow. These best practices not only stabilize prints but also protect layer adhesion. With stable prints, you can move forward to fine-tuning surface finish and performance for more advanced ABS applications.

What Causes Delamination In ABS Prints And How To Avoid It?

Delamination happens when layer adhesion in ABS prints is weak, and parts split apart during cooling. The main reason is temperature: if the extrusion temperature is too low, or if the cooling fan blows too strongly, layers fail to fuse at the right glass transition temperature. Slower print speed allows more time for one layer to bond with the next, reducing chances of failure.

You can take action by raising the extruder temperature into the proper range for your ABS filament, often between 230–250 °C, and printing inside an enclosure to protect against drafts. Waiting for the chamber to stabilize also improves consistency. These steps strengthen the connection between layers and improve print quality. Once delamination is controlled, the next concern is ensuring your ABS actually sticks to the bed during the early layers.

What Should You Do If ABS Isn’t Sticking To The Bed?

Bed adhesion problems are common when printing ABS, and poor connection between the first layer and the build surface leads to failed prints. The main causes are incorrect bed temperature, uneven build platform leveling, or a surface finish that does not provide enough grip. You should check that the bed is heated to at least 100 °C, then confirm the nozzle gap is correct during the first layer.

There are several consumables that improve adhesion: a glue stick creates a tacky layer, PEI sheets balance durability and ease of use, and ABS slurry provides strong bonding. Adding a brim increases surface area, and tape is a low-cost choice for testing. These tips improve security on the build plate and reduce warping. After bed adhesion is stable, you may still face nozzle issues that interfere with print performance.

How To Solve Nozzle Clogs Or Stringing When Printing ABS?

Clogs and stringing are common trouble points when printing with ABS filament. Burnt material, leftover plastic from PLA or PETG, or inconsistent extrusion temperatures can block flow and lower print quality. The first step is diagnosis: if no filament exits the nozzle, heat to printing temperature and try extrusion manually. If flow is partial, residue may be the cause.

The cold-pull technique is a reliable way to clear burnt ABS or other residues. Heat the nozzle, insert nylon or cleaned filament, let it cool below glass transition temperature, then pull it out to extract debris. For stringing, adjust retraction settings, lower nozzle temperature slightly, and reduce waiting times between travel moves. These actions improve surface finish and protect performance. With nozzle issues addressed, you secure smoother results and extend the capabilities of your ABS prints for more demanding applications.

What Are The Most Common Mistakes When Printing ABS And How To Avoid Them?

When printing ABS, beginners and even experienced users often run into the same issues. One of the most frequent mistakes is printing without an enclosure. ABS filament shrinks as it cools, and drafts or sudden temperature shifts reduce layer adhesion, causing parts to warp or split. Another issue is poor bed leveling, where the build plate sits unevenly, leaving gaps in the first layer and compromising security on the print bed.

Cooling also plays a major role. If the cooling fan runs too high, layers separate. If it is too low, you risk surface finish problems and excess heat distortion. Temperatures set too high burn the material and create strong odors, while too low extrusion temperature weakens the connection between layers. A mistake many overlook is filament storage. If you forget to re-dry ABS after waiting overnight during a paused job, moisture inside the plastic can cause bubbles, stringing, and weak spots in your ABS prints.

What Are The Best Practices And Pro Tips For Printing With ABS?

Printing ABS successfully comes down to preparation and discipline. The first step is stabilizing your environment. Always print in an enclosure or heated chamber to maintain steady temperatures and reduce the chances of warping. A bed temperature between 100–110 °C ensures the first layer bonds tightly to the build surface, while tuning extrusion temperature between 230–250 °C helps improve strength and print quality.

Consumables make a difference as well. Applying a thin coat of glue stick, tape, or ABS slurry gives your parts more grip on the build platform. A brim adds extra surface area and security against lifting. PEI sheets offer a clean, reusable surface finish with reliable results over many prints. You also need to consider filament dryness. Storing ABS in a sealed container with desiccant is a simple way to avoid moisture-related trouble.

Best practices go beyond settings and consumables. Keep your printer calibrated, use moderate print speeds, and monitor odor with proper ventilation. When you follow these tips, printing with ABS becomes less about fighting issues and more about achieving consistent performance. The next step in building consistency is preheating your printer before every print.

Should You Preheat The Printer For ABS?

Preheating is one of those small actions that bring big improvements when working with ABS filament. By warming up the hotend and print bed before loading material, you give the printer time to stabilize temperatures across the build plate and chamber. This extra waiting period creates an even heat distribution that reduces stress between layers once printing begins.

For best results, set the bed temperature to your target range and let the printer hold it for a few minutes before starting. Doing so helps the first layer stick more securely and improves the overall surface finish of your ABS parts. Preheating also reduces the risk of nozzle clogs from cold starts. In practice, it’s a simple step, but one that consistently improves print quality when printing ABS.

Why Should You Dry ABS Filament Before Printing?

ABS filament absorbs moisture from the air, and that small change in the material’s properties can create big issues once you start printing. When wet filament hits extrusion temperature, trapped water expands into steam, forming bubbles inside layers. The result is weak parts, poor layer adhesion, and a rough surface finish. You may even notice inconsistent extrusion or hear popping sounds as the filament passes through the nozzle.

To avoid these problems, it’s best to re-dry your spools before printing ABS. A dedicated filament dryer, a low-temperature oven, or a food dehydrator all work well. Even after long prints paused overnight, re-drying is necessary to restore filament quality. Taking this action improves print quality and ensures the strength and durability you expect from ABS prints.

Why Monitor The First Layer During ABS Printing?

The first layer defines everything that follows. If it does not bond securely to the build surface, your ABS parts have a higher chance of lifting off the bed or warping. Watching closely as the printer lays down that initial layer gives you information about bed leveling, bed temperature, and extrusion temperature in real time. You can act quickly to correct issues before wasting hours of print time.

Common problems include edges curling upward, uneven extrusion, or poor connection to the build plate. Users often fix these by applying a glue stick, ABS slurry, or tape to improve adhesion. Monitoring the start of a job may feel repetitive, but it is one of the best practices for consistent results. A few minutes of waiting ensures long-term print security and stronger ABS prints.

How Often Should You Calibrate Your Printer For ABS?

Calibration is one of those maintenance tasks that pays off directly in print quality. Printing with ABS requires precise control of extrusion temperature, bed leveling, and chamber stability. If the printer drifts out of calibration, you may see layer adhesion issues, surface finish problems, or warping.

A good practice is to check your Z-offset every 5 to 10 prints. This quick adjustment keeps the nozzle at the right distance from the bed and maintains a smooth first layer. Beyond that, performing a full mesh recalibration once a month is recommended. This includes verifying the build platform, chamber temperature, and bed surface condition. By keeping calibration regular, you secure reliable ABS parts and prevent the performance trouble that often comes from ignoring small changes in your printer’s setup.

How To Monitor And Control Print Quality During ABS Printing?

Real-time monitoring is one of the best practices you can adopt when printing ABS. The material has valuable properties like heat resistance and strength, but issues such as warping, fumes, or weak layer adhesion can ruin ABS prints if left unattended. By observing the first layers on the build plate, you confirm that bed temperature, extrusion temperature, and the connection between nozzle and build surface are stable.

Webcams and sensors give you a way to keep watch without sitting in front of the printer. Tools like OctoPrint paired with the Spaghetti Detective plugin can detect failure patterns, such as lifted edges or stringy extrusion, and send notifications. This early warning lets you take action before wasting filament and time.

Common signs of trouble include corners of parts curling, odor becoming stronger as cooling fans overcompensate, or inconsistent surface finish. You can often correct these by applying consumables like glue stick or ABS slurry, or by adjusting chamber ventilation. Monitoring means more than waiting—it ensures security for your ABS parts, improves print quality, and increases the chances of success across a variety of items and models. With this guide in mind, you know what issues to look for and when to intervene.

How Much Does It Cost To 3D Print ABS?

Printing with ABS is affordable, but you should understand the cost breakdown before starting large jobs. ABS filament typically costs about $0.02 per gram, making it more expensive than PLA but cheaper than some materials like PETG. On a typical printer, electricity use averages 0.1 kWh per hour. At a rate of €0.25 per kWh, that adds about two to three cents per hour of operation.

Consumables also add up. A glue stick, tape, or sheets like PEI wear down with use, averaging about €0.03 per hour. When you combine filament, electricity, and consumables, the cost to produce ABS parts is still reasonable. You benefit from strength, resistance, and performance features that make the material a favorite in applications beyond injection molding. By balancing cost with quality, you get reliable results without overspending.

How Does ABS Compare To PLA And PETG?

When you look at ABS alongside PLA and PETG, you see how chemical and physical properties shape the choice of filament for 3D printing. ABS has a glass transition temperature of about 105 °C, making it more suitable for heat resistance than PLA at 60 °C or PETG at 85 °C. That higher temperature range is one reason ABS parts hold up better under stress and resemble the durability of injection molding.

PLA remains the easiest material for users thanks to low extrusion temperature and simple adhesion on the build platform, but its lower strength and higher brittleness limit demanding applications. PETG stands in between. It offers better layer adhesion than ABS and more impact resistance than PLA, yet ABS still excels when you need both performance and surface finish.

Izod impact testing shows how clear the difference is. PLA measures around 15 J m-1, PETG reaches 80 J m-1, while ABS delivers 200 J m-1. That gap explains why ABS filament continues to be favored for functional parts and models where toughness matters. When combined with a heated bed, enclosure, and proper settings, ABS prints achieve results that outperform PLA and match PETG in versatility.

| Factor | PLA | PETG | ABS |

| Density | 1.24 g cm-3 | 1.27 g cm-3 | 1.04 g cm-3 |

| Glass Transition Temperature | 60 °C | 85 °C | 105 °C |

| Izod Impact | ~15 J m-1 | ~80 J m-1 | ~200 J m-1 |

| Yield Strength | 50 MPa | 53 MPa | 40 MPa |

| Young’s Modulus | 3.5 GPa | 2.1 GPa | 2.3 GPa |

| Heat Resistance | Low | Medium | High |

| Layer Adhesion | High | Very High | Medium |

| Surface Finish | Glossy | Glossy | Matte |

| Odor | Sweet | Mild | Strong |

| Warping Risk | Low | Medium | High |

| Bed Temperature | 60 °C | 70–80 °C | 100–110 °C |

| Extrusion Temperature | 190–210 °C | 220–250 °C | 230–260 °C |

| Enclosure Needed | No | Recommended | Yes |

| Cost (per kg) | $15–25 | $20–35 | $15–50 |

| Applications | Prototypes | Functional Parts | End-Use Items |

Conclusion

Printing ABS successfully means balancing cost, temperature control, and best practices that protect print quality. ABS filament offers a mix of strength, impact resistance, and heat resistance unmatched by PLA and even PETG in certain applications. You can produce parts that withstand higher temperatures, resist warping with the right chamber and build plate preparation, and deliver a finish that supports real-world use.

At the same time, ABS prints demand attention to detail.

Bed temperature, surface adhesion aids like glue stick or ABS slurry, and an enclosure all reduce issues like fumes and layer separation. If you apply iterative tuning and monitor your printer closely, you can take full advantage of ABS capabilities. With consistency and patience, printing ABS becomes not just manageable but highly rewarding.